|

I did decide to do the glue up. I first glued up the neck. I really hope it all went well. It took a while to get the clamps right. And maybe the glue was too thick. It looks good now but I don't know if I can count on that. Otherwise the neck look goods. It appears centred on the body and the projected height is right. After the neck was done I also glued up the saddle. Now all its all done!

0 Comments

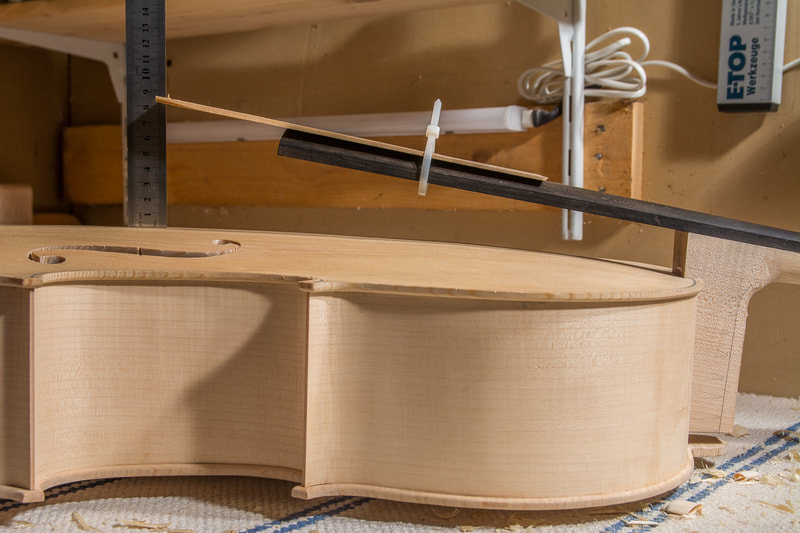

One last thing to do before glueing up the neck is to put the saddle on. It could also be done afterwards but in my small workshop it is easier when the cello is still small. I had prepared a bit of left over ebony from the fingerboard already. Similarly to the neck mortice, I marked the width and depth of the saddle and then cut it out. Once the cello body was ready I could shape the saddle appropriately.

I smoothed out the curves of the neck a little more. First with a fine rasp, then with a file and in some parts also with the knife. In the end I asked my son how the neck and all feels. He said it feels all very good. So I thought maybe I can finish the neck refinements.

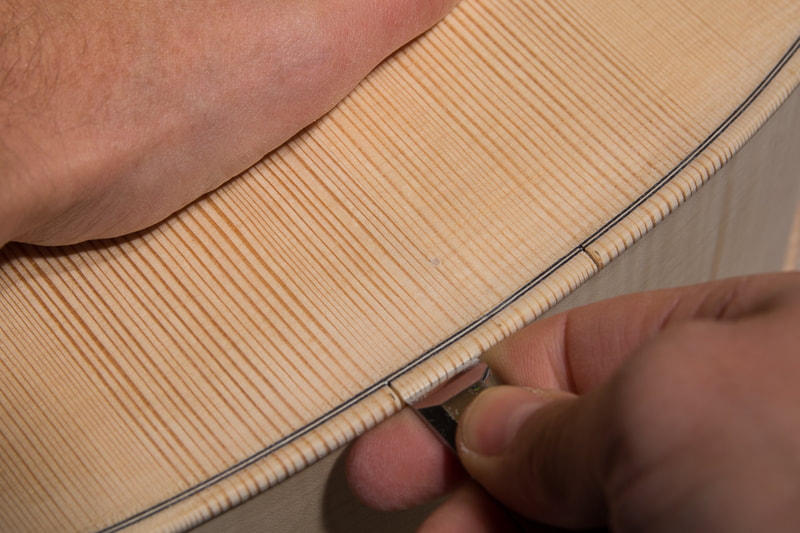

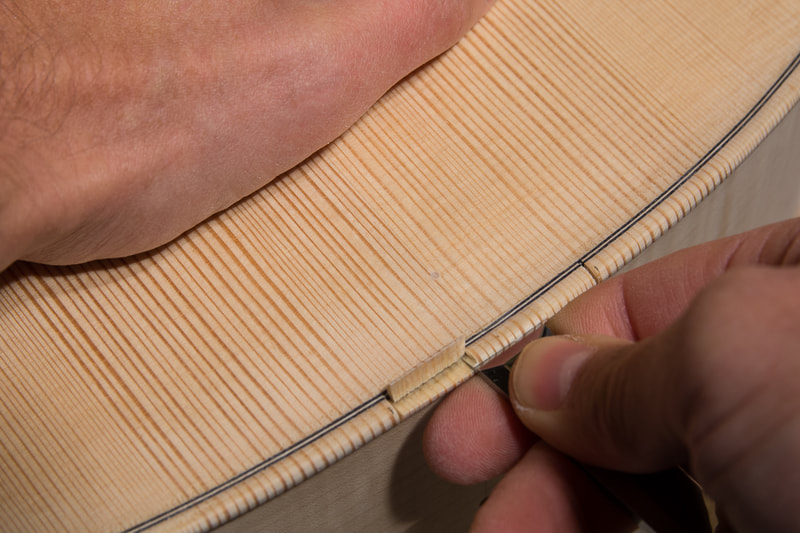

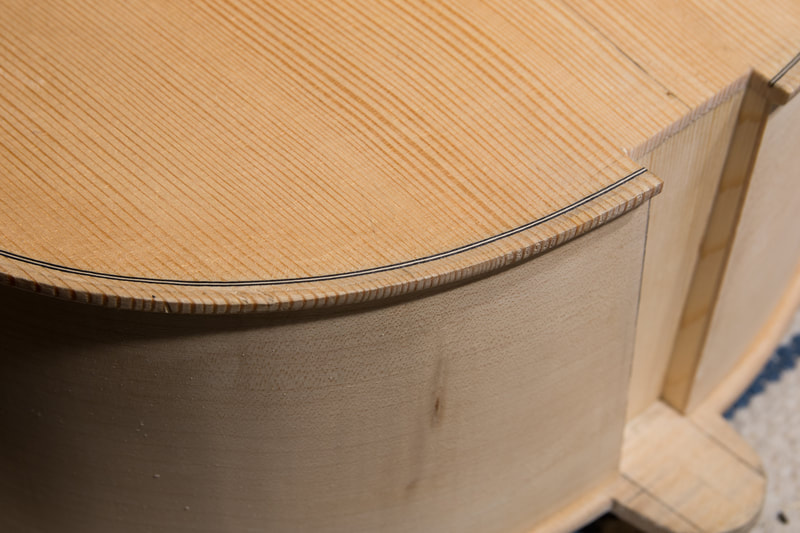

Today I wanted to get both the body and the neck more refined before glueing them together. I had already rounded out the corner of the edges towards the ribs. Now I did the outer edge. The idea is to first make a bevel with a shallow angle, followed up with a second one with a steeper angle and then smooth the bevels with some sand paper. At first I wondered why it is done this way but I think I realised it while doing it. Making a bevel is pretty straightforward, and if the lights are correctly set one sees very clearly the flat bevel created. It is then quite easy to make sure that both the bevel angle and the width of the bevel stays constant.

After having done the back and front edges I started also refining the neck. I sawed off some extra material from the heel and also started shaping. Chalk fitting is done in the end to ensure a good fit every where. Some chalk is put on the heel of the neck before it is pushed into position. Chalk should stay uniformly all over the mortice. And that is indeed mostly the case. There are some spots at the bottom on the sides without chalk but in the centre it goes all the way from the top to the bottom. I will do some refinement but the fitting is now more or less finished. I think I will work first a bit more on the neck to get it finished as this is easier when the neck is not yet attached to the body.

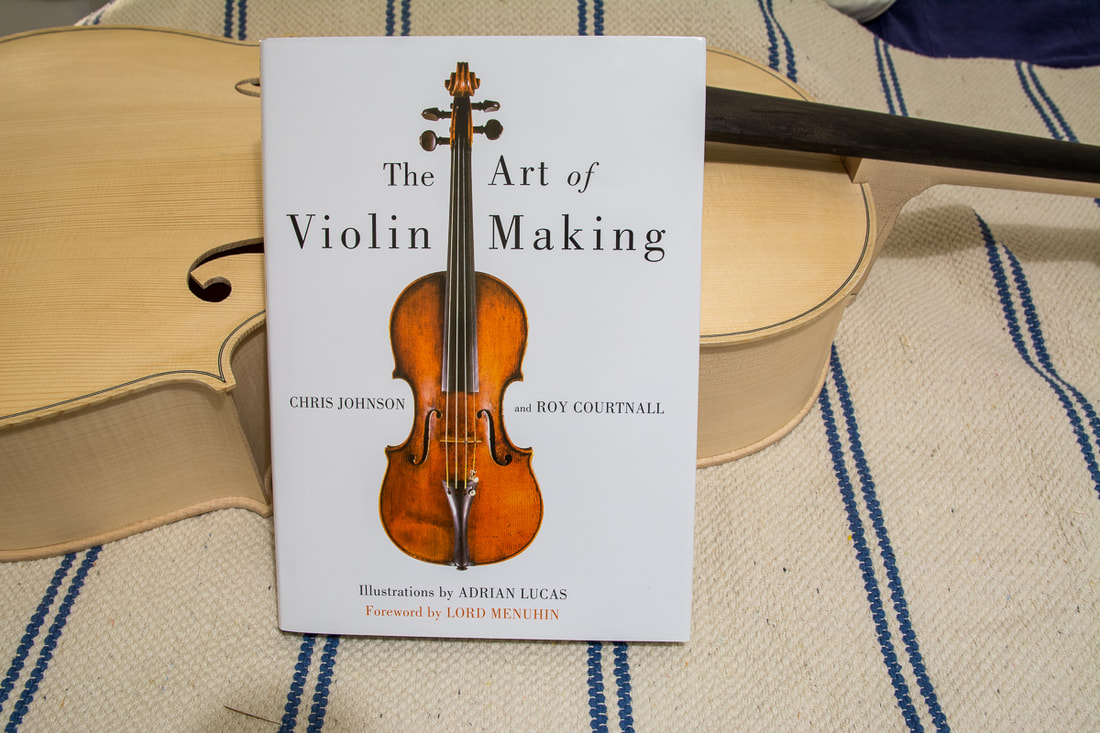

I got a new book today. It was recommended to me by a luthier. So far it really seems excellent. Very detailed with good illustrations and photos. I checked what they write about the grain direction of the blocks. This is what I found:

"...so that the blocks can be glued to the mould with the fibres running away from the top. This will aid carving later, especially when the neck mortice is cut out." That is spot on and I hope I had had that advice earlier. I think none of the other books I have read put it so clearly. I think they mention splitting the blocks and etc. But this one not only says that but also that one should even ensure the fibres are running away from top. Anyways, I am very happy with the book. It wasn't cheap but I think money well spent. Made good progress today, the neck is almost fitted. It needs to come down still ~1 mm but then it is good. The projected height is then what I want (72 mm) and the height of the bottom of the fingerboard at the heel above the front is 19 mm.

I forgot to put links to some good resources earlier so here you go: www.derekroberts.co.uk/making/neckjoint.htm osnesviolins.com/10.Fitting%20the%20Neck.htm YouTube: Davide Sora Lavorazione e incastro del manico di violino YouTube: Jon Magnum How to Build a Fiddle - Part 10 Attaching the neck, nut & saddle Now I started to measure the correct configuration for the neck. Based on the book by Baker, the projected height of the fingerboard at the bridge is 70 mm. I read somewhere that the height of the fingerboard usually gets a little smaller in a new cello. I am therefore aiming now at 71-72 mm so it is still something 10 mm too high. Luckily also the heel is roughly the same amount too high. This means that I don't need to try to change the angle of the neck, I just need to bring it down. I will now do the rest of the work mostly with files and the grain direction doesn't matter too much anymore. A chisel is actually also quite handy as a scraper to ensure the bottom is flat. The orientation of the neck in other ways. It all looks pretty good. No need to do major adjustments, just make the mortice a little deeper and wider, mostly to the one side. as the centre of the neck doesn't quite match the centre of the body. But it's not far off.

The grain direction is pretty annoying. I figured that the best was to go across the chain carefully. At least for the bulk of the material. The fine tuning can be done with a file. I hope. I went as far as I dared today with out checking the orientation or projected height of the fingerboard etc. I still have enough wood all around the mortise to make sure the neck can be fitted as required.

I noticed the problem with the block grain direction already when shaping the blocks. At the time it wasn't too much of an issue as I could shape the blocks from the the other side then. This is different now since the button on the back prevents me from coming with the chisel from the right direction. In fact I'm quite happy how few mistakes I've made until now. Well, ones I am aware of in any case. |

AuthorMy son is outgrowing his cello soon. Could there be a better reason to learn how to make one :). Archives

April 2021

Categories

All

|