|

I proceeded with the back rest today. Last time I notice that the way I had first designed it was not going to work. It really needs to be tilted slightly to make it more comfortable. The problem is how to do it. I wouldn't want to have multiple rungs, though maybe that is OK too. For now I wanted to concentrate on the top though. Trying to find a nice width and a good way to get some angle into it.

0 Comments

I started to work on a chair to fit the table. This is now just a prototype from pine. I am trying the get the proportions right and make it comfortable to sit on. The back rest is not glued in yet. There probably needs to be another transverse back rest to provide good support. Also the chair is maybe too narrow as it stands, or at least the feet should be a little more apart. It is an interesting experience making a chair. Lot's to think about :).

The table is finished, wrapped and ready to be delivered to the customer. The delivery went smoothly and we managed to carry the table to the second floor without any issues. I didn't take any photos but the customer should send me some later on.

It has been a great experience and as I was making the table people commented it very nicely. Can't wait to start the next project, what ever that will be. It's ready! I put the third and final coat on today. The surface is really nice. I have really enjoyed making this table and I am very happy with how it turned out in all respects. In the beginning I was wondering if the grain of the wood is too string but I think in the finished piece it is just right. It is a big table and on that scale the grain is really nice. The joinery also worked out well and legs are solidly attached to the table top.

The first coating is on! I am using Bona Hard Wax Oil. I like the surface finish it gives and one still feels the wood underneath. The finish really makes the beautiful grain of the wood stand up. I will put one coating every day now to get a a total of at least three coats.

Everythings ready for the finish. I was hoping to put the first coat on already today but that didn't work out. The sanding and putting the final touches always takes longer than one expects. But the table looks really nice and and the finish will make it look even better. I almost want to keep it for myself!

I cut the bottom supports of the table to length and covered the ends with plugs made from the same pieces of wood. The supports don't go continuously through the while width of the table to allow the wood to contract and expand with the seasonal variations in humidity. I also attached the legs to the supports and cut the table to width. The cutting of the table to width was rather nerve-racking but it went pretty well in the end, only minor burns on the wood which I could remove with a plane. I still need to fit and fix the smaller cross supports before I can apply the finish. So a little way to go still but not all that much.

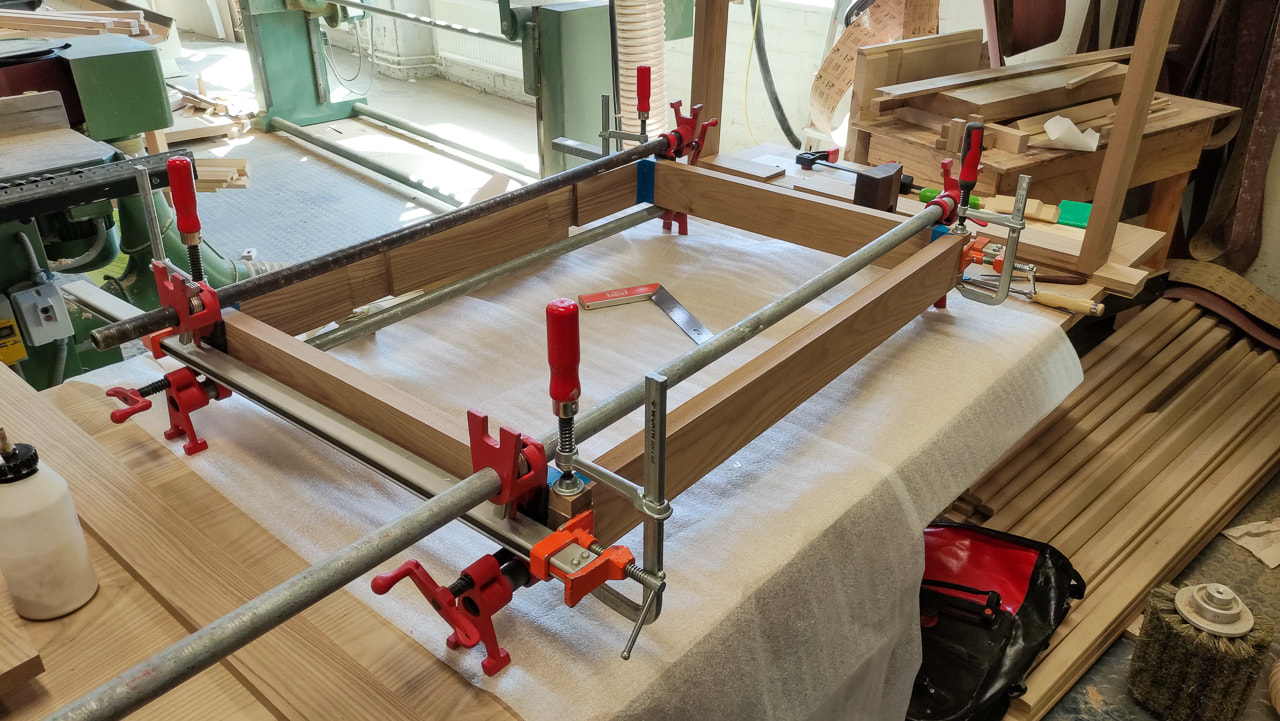

I managed to fit all the pieces together and glue the legs together. Everything went really well without any issues. I used a chisel and a router plane to fit the finger joints. I haven't used a router plane a lot but it suited the job perfectly. It was really easy to thin shavings from the tenon to get a perfect fit. There will probably be no more gluing, all the remaining pieces will be screwed together.

I had a great day today! I milled all the remaining pieces to final dimensions. And also managed to do all the joinery at least roughly. For the joinery I need to still fit but the bulk of the work is done. I forgot to cut the cross pieces to length so that also still needs to be done. If all goes well, next time I might be able to turn the table on its legs.

|

AuthorI have always been making things I need, and have wanted to learn the skills required to get the job done. My greatest passion is however woodworking. Archives

May 2022

Categories |

RSS Feed

RSS Feed