|

I am now at ~5 mm everywhere. Some places in the lower an upper bouts are a little less. The front plate now weighs 429 grams.

I have been doing this now with the graduation punch, the pencil gauge and a scraper. Mostly with the latter two. I find it easier to use the pencil gauge to mark up high spots. My process is as follows:

It is not quite uniform, nor is it exactly 5 mm. But I think it is close enough for now. Maybe I will move to the back next, hollow it out and start the graduation. Once both plates are fairly close I can then fine tune and match the tap tones of the plates. I am not quite sure how important it is for the tap tones that I have cut the sound holes already. And in fact maybe I could finish the sound holes next. Will need to think about this a bit.

2 Comments

I reduced the thickness further today. I am nearing 5 mm everywhere. The weight is now 460 grams. It seems like a lot when comparing to some other values I have seen around. Table 3 in www.platetuning.org/html/modes_-_tuning_plates.html lists the belly (front) plate weight for 1/2 cello at 295 grams. That seems like a lot of weight to reduce still. The table is based on some theoretical correlation and is the weight which would be expected by scaling a full cello front. I will keep the number in mind but not aim for it.

I just realised a small mistake I made in hollowing out the front. I didn't leave enough flat area around the bottom and top blocks. Or maybe just enough at one end. I thought I had marked the allowed areas properly but clearly I hadn't. One should always be alert and not trust that one did all correctly previously. I hope it doesn't matter too much. I started with the graduation of the front. I am bringing the whole front to a uniform thickness of maybe ~5 mm. I think that should be safe so that I have still material to remove. Today I managed to get it to ~6 mm everywhere. The photo below shows light shining through the front plate (where the circle is). The unevenness is mostly due to differences in wood density. The plate itself is pretty consistent. Only where the two plate halves join in the middle is the plate actually thicker. This is because I need to plane one side in the opposite direction from the other. In order not to plane against the wood, I have to stay a bit off the centre on both sides leaving a small ridge in the middle.

I also had some good exchange of emails with maestro Kimon today. Thanks maestro! We discussed how to best do the graduation and the tuning of the plates. I haven't found good material on how to do it for a small cello like this 1/2 cello I am making. It is probably not possible to get the tap tones of a 4/4 cello without the plates getting too thin. The current plan is to keep the plate thicknesses reasonable. And rather than concentrating on the absolute frequencies of the tap tones, I want to make sure that the tap tones of the back and the front have a good relation to one another. I did a bit of scraping today. Th back is a little rough still and needs to be refined but I am pretty close to the final shape. I think Barker wrote that one should be careful not to take templates etc. too strictly. And in fact Strobel also stresses that the templates were for his cello but we should make our own cello. I am taking that as chance to make my own choices. Once refined, the current arching of the back is beautiful in my opinion. I feel more and more that I would now really benefit if I had well made cello to study. Reading books can't quite replace that.

I did good progress this weekend. I continued with the arching. I got pretty close to the the final shape. Still need make sure the arching is nice and even. I also made two more knives, a 12 mm left handed and a 18 mm right handed. Now I have a nice set to work with.

I decided to start with the transverse templates next. I started by planing each template position to down most of the way and finally smoothed the surface between the stations. I didn't go all the way yet, there is ~1-2 mm more material to remove fairly consistently still everywhere. I don't want to have nasty surprises with the curly maple when I come to finish it with a scraper. I only managed to do one side today.

I started the final arching of the back. I am first fitting the longitudinal template. I thought I went too close to the final shape with the rough arching of the front so I made sure to leave more material for the back. As a result I have a lot more to remove this time. But it is not too bad actually. I have a chance to use the plane a bit and get used to the curly maple. It is easier going than I thought. I tried with a block plane (which seemed huge after the small fingerplanes) and a larger fingerplane, but I seem to always come back to the small fingerplane. It fits the fingertips so well and has great sensitivity. I didn't yet quite where I want to get to with the longitudinal template, need to continue tomorrow. The gorgeous pattern of the maple is starting to emerge.

I did the first part of the fluting today. I went with a 10 mm sweep 7 gouge around the edge up to the line drawn 2.5 mm from the edge. The next step is to widen it and merge with the arching of the back.

No much progress on the cello today. One of the buttons on my old Nikon D7000 stopped working reliably. I've had it for many years now and bought it second hand so I am not too disappointed. I like it lot though and it was a shame to realise that fixing it would likely cost more than what I originally paid for it. Luckily somebody close to where I live wanted to sell the D7100 for a very reasonable price. Anyways, finding and getting the camera took most of my free time today. I did manage to shape the transverse arching guides for the back and marked the edge for the back. Tomorrow I can start the final arching of the back with the fluting around the edge.

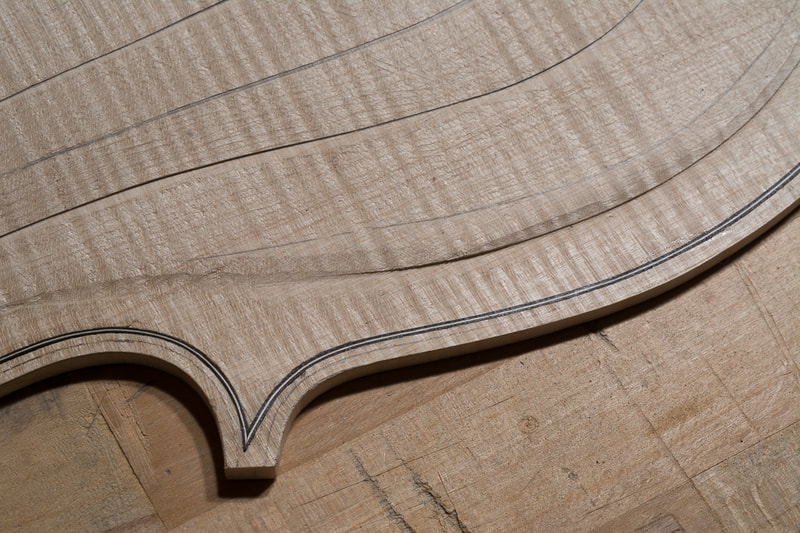

The photos show how the plates look at the moment. Both have the purfling all round. The front plate has been arched and hollowed, and the ff-holes have been roughly cut. I still need to do the graduation and finish the ff-holes. The back has been roughly arched and has the purfling. The arching needs to be finalised next and then the plate needs to be hollowed. And both plates need to be tuned up.

|

AuthorMy son is outgrowing his cello soon. Could there be a better reason to learn how to make one :). Archives

April 2021

Categories

All

|