|

I fit the strings yesterday! I wanted to concentrate on the strings so I didn't take any photos. But it was pretty straight forward in the end. I found a good, clear video on you tube which explained the process very well. The video is by Jonathan Humphries, How to Replace Cello Strings | Basics of Cello. He has lots of videos about cello, also on how to play it. They look good to me, but as I don't play the cello myself I can't really judge. Maybe I should start learning to play the cello too.

The strings are Larsen Strings for 1/2 cello (larsenstrings.com/larsen-fractional/), they were recommended by Pekka.

0 Comments

I had fit the pegs so that they only just went through the peg box. My first idea was that I would do them properly with Pekka. But now I want to put the strings on and don't want wait until next week. So I will do all by myself first and only check with Pekka afterwards.

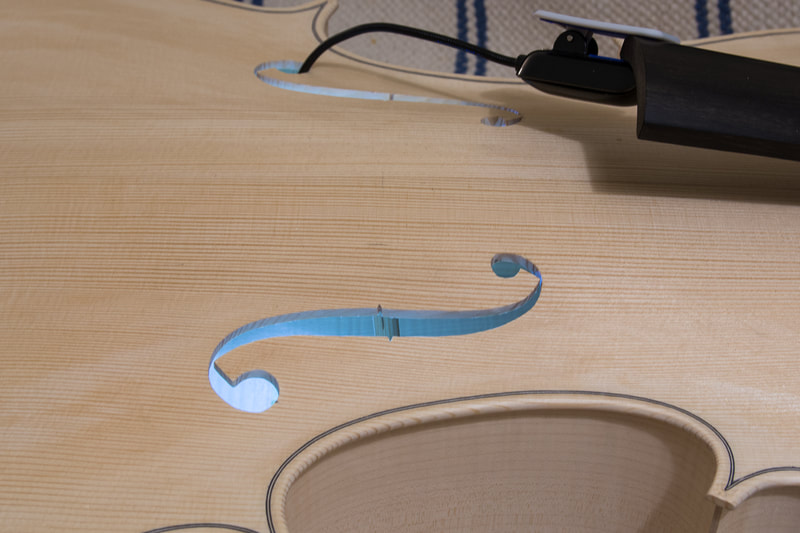

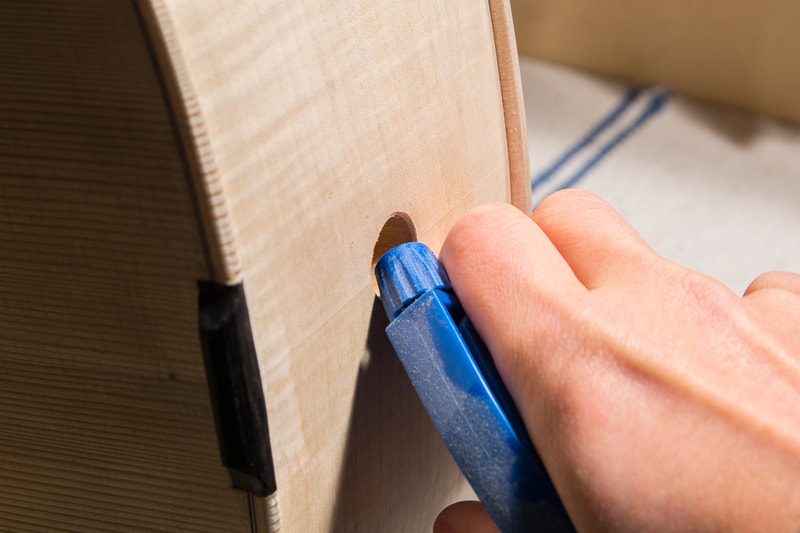

So I reamed the holes bigger until the shaft of the peg was about 15 mm. Did I mention already that I really need to practice reaming. The pegs are not straight. But I will let that not disturb me too much now. After the pegs went deep enough, I drilled a 1.5 mm hole in each for the string. All that remains now is to put the strings on and tune it! Now that the sound post is in place it is time to finish the nut. At least mostly. I will prepare it so that I can put the strings on but will not fine tune the clearances to the fingerboard before the final set up. They are quite close so Elias should be able to play it like this too. I used a file to round off the nut towards the pegbox. The edge towards the fingerboard should stay crisp.

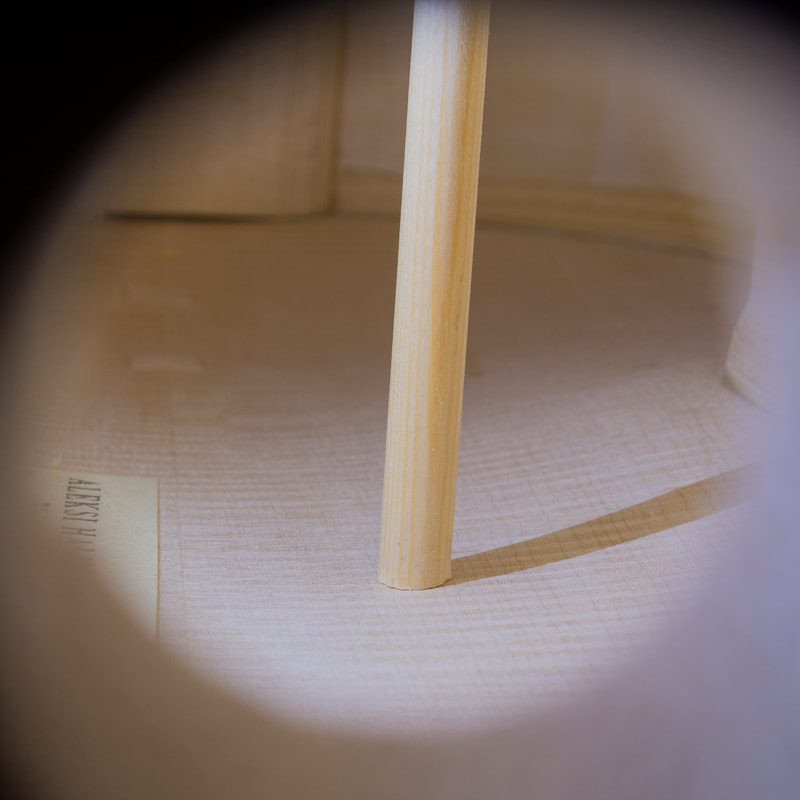

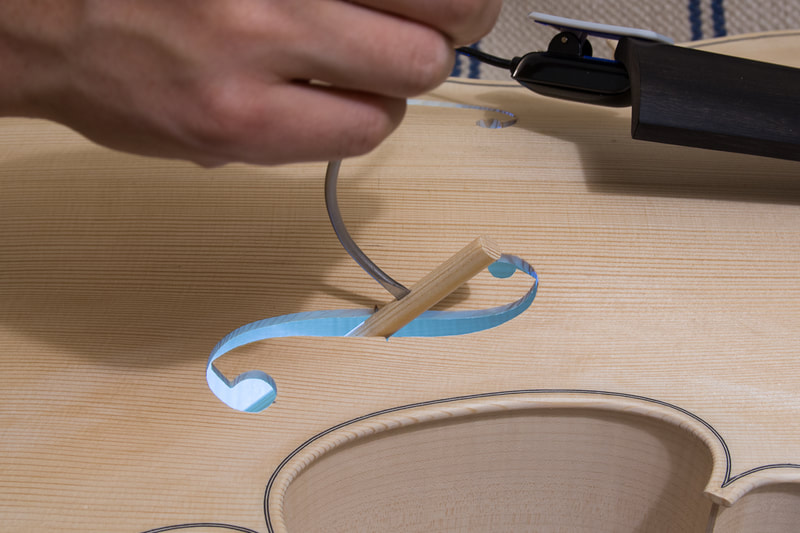

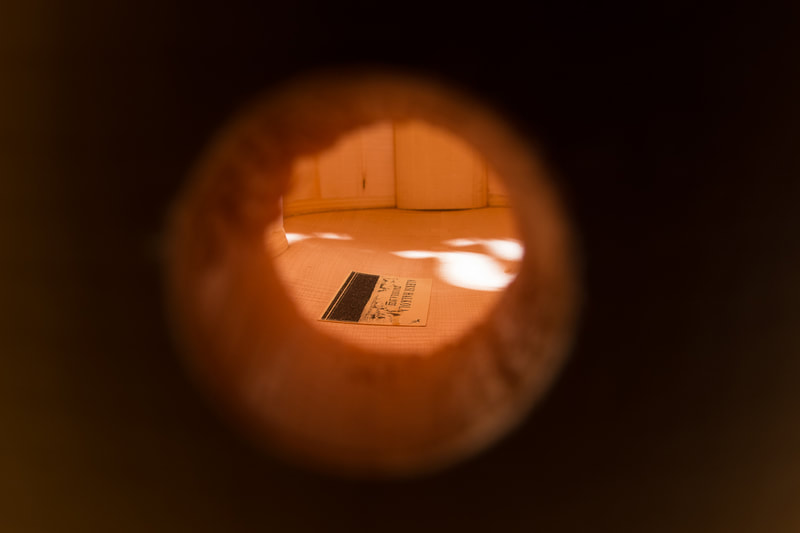

Of course I couldn't keep my hands of the cello for very long. I did a few things to make the process better. I tied a string to the sound post so that I could easily pull it out of the cello if needed. And I used some tape to attach the setter to the post. That way I could quickly put it in and out and adjust a bit. From what I have read it is important that that sound post fits exactly to the front and back. For this initial "dummy" sound post I think the fit is good enough. It is there now so that I can fit the bridge, and then the strings and get some first sound so that I can make sure there are no really, really bad problems with the sound. The final setting and tuning will anyways be done after the varnishing.

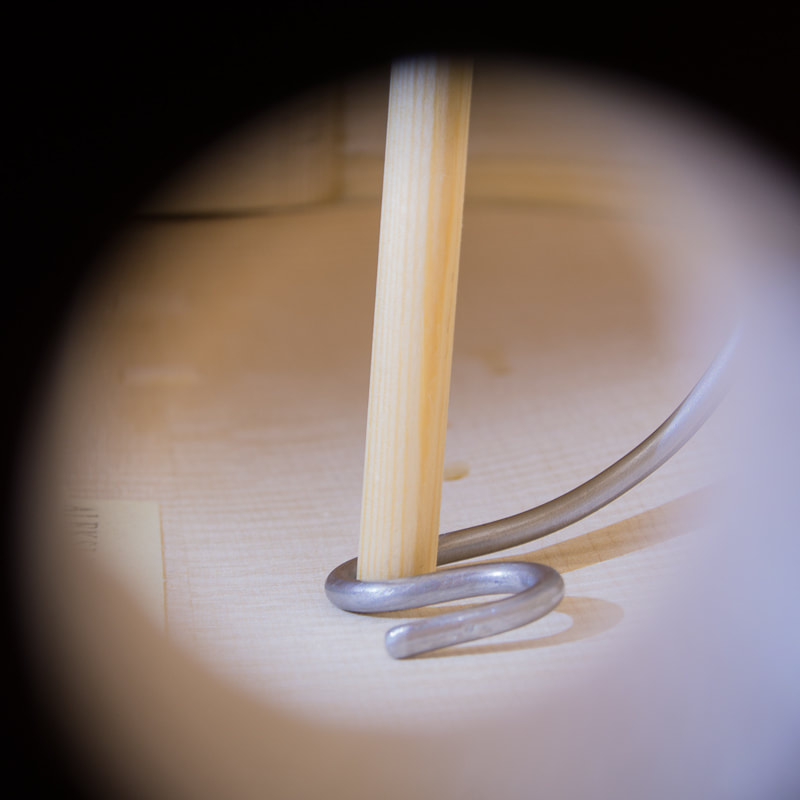

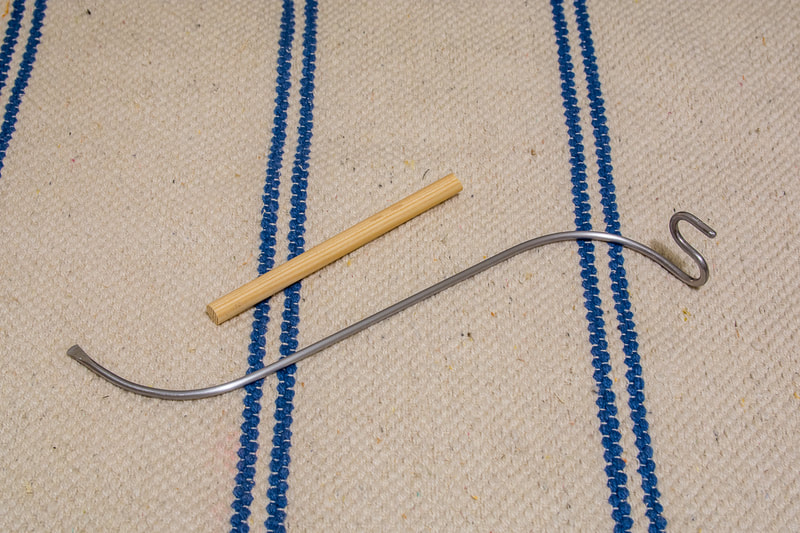

I started with the sound post today. First I made a sound post setter. It's just a piece of thick wire with a sharp end to put the sound post in and a bendy end to move the sound post around. I got a little frustrated when trying to fit the sound post it kept falling of the setter in the cello. And so I decided to stop before I would do something stupid again like when reaming the end pin hole.

After having done the end pin, I started fitting the bridge. The bridge is quite tall so I need to remove a lot from the feet, other wise the heart comes too close to the strings. The bridge really should be fitted after the sounds post is in place. Which it isn't. That's why I will only go so close. The thickness of the bridge is actually already pretty close. I think I will only thin the upper part to ~2.5 mm but other wise leave it as is. At least until the cello is varnished. My plan now is to get the first sound out, make sure I don't need to open the cello again. And after that varnish and finalise the fitting of the sound post and the bridge. Not sure if this plan makes sense. But anyways, I will now do what I can, then meet with Pekka again to put the sound post in and get his feedback and help with the rest and then varnish. Hopefully soon! My plan still is that the cello will be finished this year.

I decided not to glue the end pin in its place, and made plug and glued that instead. With the hole filled I could restart the reaming process for the end pin and this time make sure I don't do anything stupid. And that worked out nicely. I left the end pin now ~5 mm proud of the surface of the cello. That leaves some room for change in the hole and end pin due to humidity or compression of the wood when the strings pull the end pin up. One doesn't even notice the fix unless one takes the end pin off, which hopefully won't happen very often.

I also got the reamer for the end pin from Pekka. He told me that it would be good if the end pin pointed a little towards the back and to the left. It would make the end pin support the cello better once in the playing position. I got everybody to help with drilling the larger pilot hole for the end pin. My wife checked the direction from the side, the children help the cello, and I drilled the hole. That went really well.

Pekka had told me that wetting the wood some what would make it easier to ream the hole. So that is what I did. I reamed slowly so that I managed to get the end pin in. We tested it with Elias so that it was good and I only needed to make the end pin go a few more centimetres further in. And then I did a mistake. I don't know why, but I thought the direction was too much to the side and thought I could still correct it. There was at least 2 cm more for the pin and I thought that it enough to start fixing the direction. Well it wasn't. The end pin is now too loose. I don't quite know what to do now. One option would be to glue the end pin in place. Another to try to fill the hole and start again. And yet another to get a bigger end pin and try to fit it. Disappointing. So far I have managed to avoid any bigger mistakes. And now this. I was probably too eager to get the first notes out of the cello. On this new thing I should have just done things really slowly and carefully. Especially with the experience with the first peg. Oh well. Need to think of something now. Maybe glueing the end pin in place would not be too bad. I will call Pekka tomorrow and see what he thinks. I met Pekka Untamala again today. We had a good discussion on the next steps. He instructed me on the important things to consider with the pegs, the end pin and the bridge. On top of this he also lent me some of his tools needed to fit them.

I first started to fit the pegs. With the first peg I learned how slowly one needs to go so that the pegs do not end up too loose. With the first one I made the mistake. Luckily I had shaved the peg smaller than it came and so I could fit one of the other pegs into that hole, just needed to shave less off of that so that it would be OK. I left all the pegs now too long and they all go only a little through the hole. I want to do the final fitting with Pekka. The nut is the final missing piece. It supports the strings at the neck. I can use the left over piece from the saddle to make the nut. I first angled the side towards the pegbox appropriately to follow the angle of the pegbox. After that I filed the top surface of the nut to follow the curvature of the fingerboard, leaving ~2 mm proud. Once that was done I could shape the ends. The top still needs to be shaped nicely so that the strings can gracefully turn from the fingerboard into the pegbox.

I cannot quite finish the nut now. I had left the fingerboard a little long and need to finish the end of the fingerboard properly before I can really match the nut. That probably needs to wait until after varnishing since to finish the fingerboard I need to take it off the neck which I plan to do for the varnishing anyways. |

AuthorMy son is outgrowing his cello soon. Could there be a better reason to learn how to make one :). Archives

April 2021

Categories

All

|