|

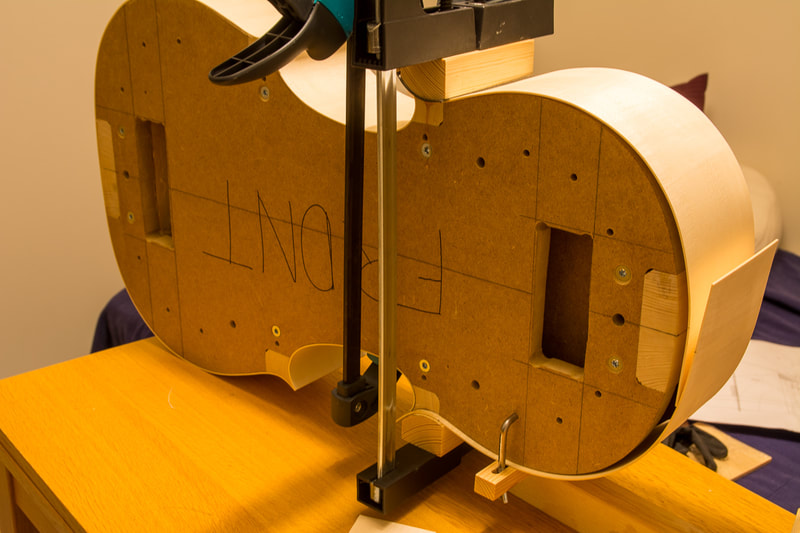

The rib structure is finished for now. The linings provide structural rigidity for the ribs and the shape of the outside is now well defined. I will not remove the last layer of the mould until the plates are ready to be glued on so that the ribs keep their shape. Once the last layer is removed, the blocks still need to be shaped.

0 Comments

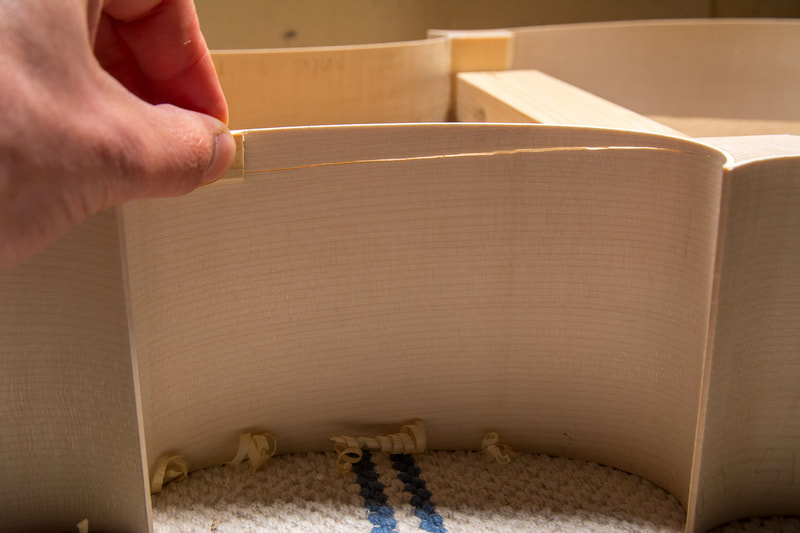

Before fitting the linings I thought it best to glue the crack. This way I don't have too many operations at the same time and I can put the clamps properly. The rib had cracked cleanly and with a knife I could put plenty of glue in the crack.

I am not sure if I remembered to put soap on all parts of the plate when I glued the ribs. Need to keep that in mind the next time. And also check for that before I start forcing the mould plates out. Anyways, I think this will to be an issue at all in the end, especially since the lining will strengthen the crack nicely. I can move to the other side now. Removing screws and pulling the mould plate out should be easy right. Well, it still requires care. Unfortunately I wasn't being careful. One of the ribs had gotten glued to the plate and cracked as I removed the plate. I only noticed this afterwards. Had I being careful I might have noticed this earlier and been able to loosen the glued by heating the area up. Luckily the crack is on the edge of the rib and I think it wont be an issue at all once the linings are installed as the lining is just about wide enough to cover the whole crack.

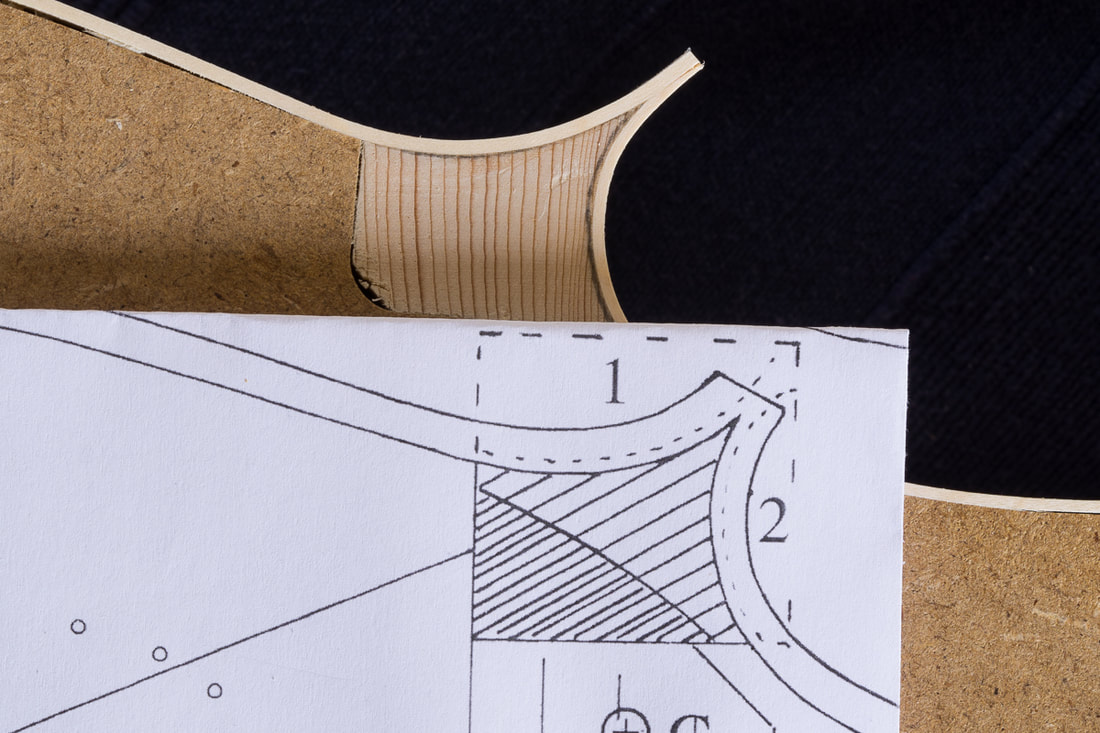

Unfortunately I haven't had time to do much in the past days. But today I finally had some time again. I shortened the upper corners considerably. I am not too happy with the shape. Not quite sure why that is though. And unfortunately I don't have much to compare to. Maybe the c rib should go straighter out to the side and the upper rib could have some more curvature at the tip.

I don't quite understand the shape of the corners in Stroble's drawings. He does mention they are drawn from his templates and hence the lines are meant to be cut out. The dashed lines showing the outside surface of the ribs converge and I cannot figure out how to make them join within the drawn corner of the front and back. My corner is little different from the drawing. It was my attempt to make the ribs join over a shorter distance. I don't like the look of the corner now. I will make it shorter but I am not sure quite how to get nice looking curves. I suppose I should have thought about this more before glueing the ribs.

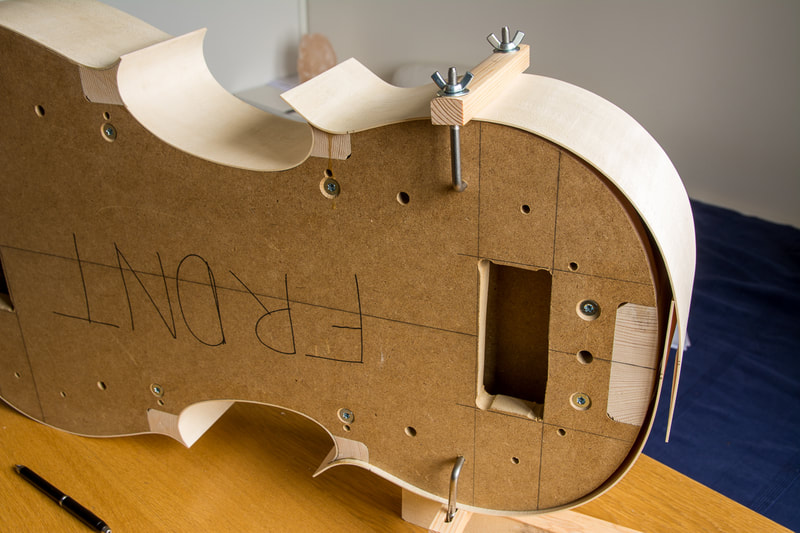

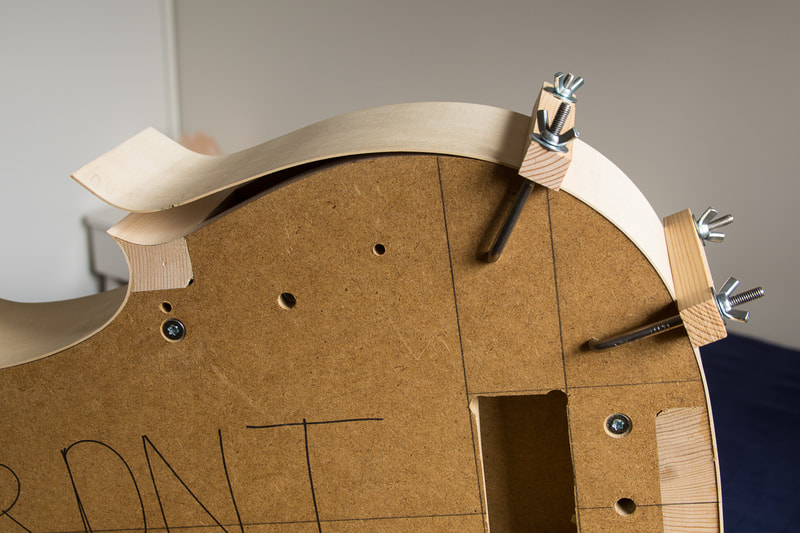

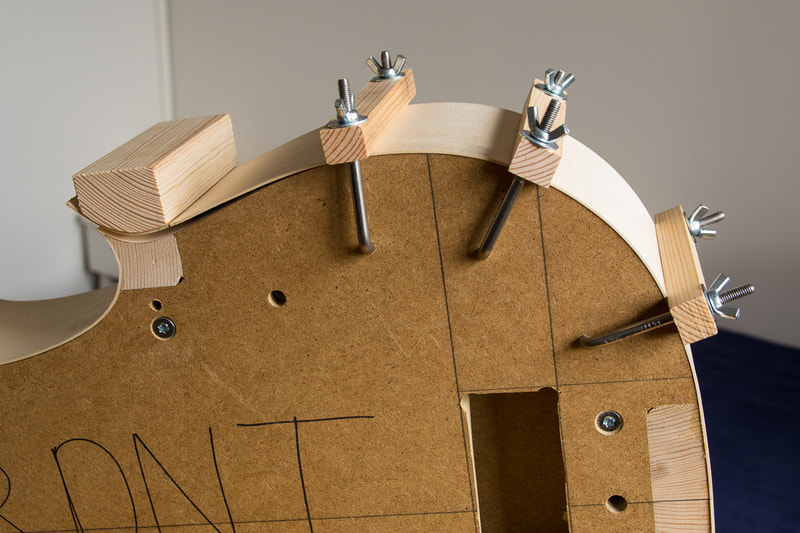

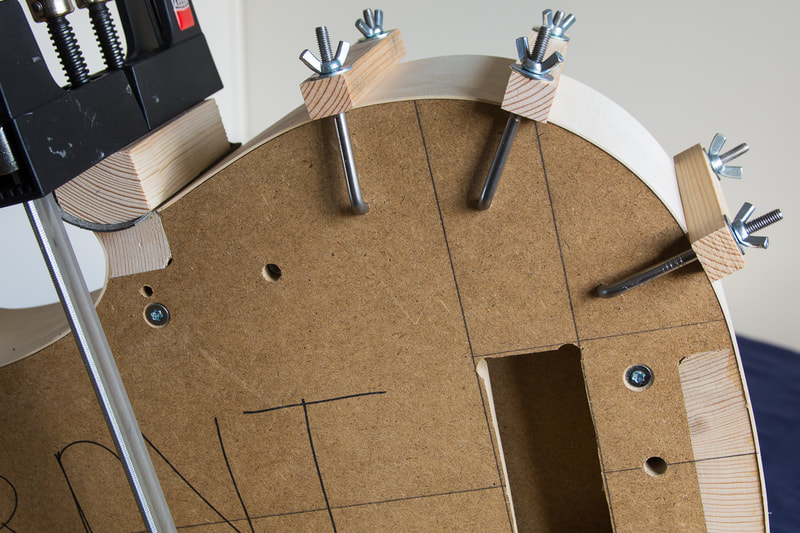

Before glueing the upper bout ribs to the upper block I shortened the ribs to proper length. The joint doesn't need to be tight so left a small gap between the ribs at the top. I then glued both ribs at the same time to the upper block.

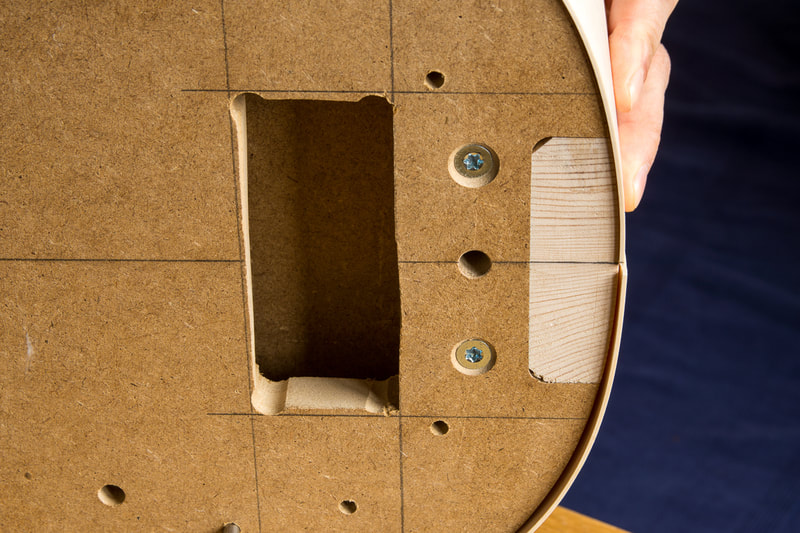

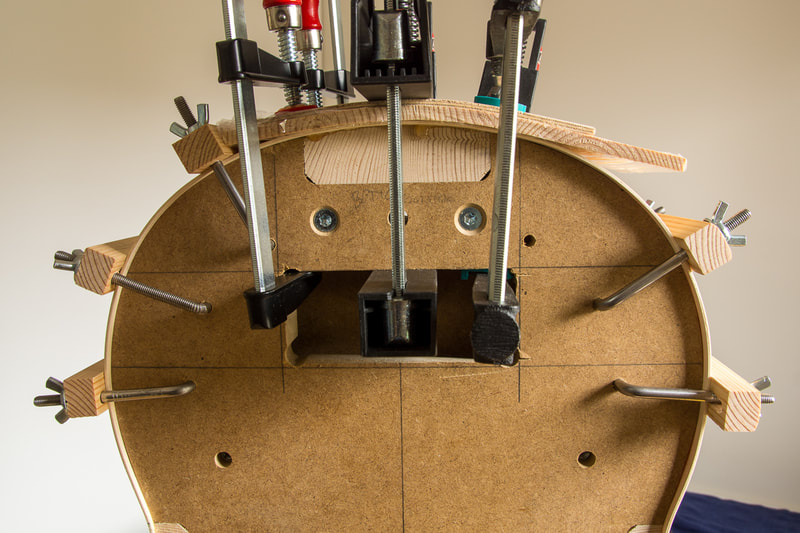

I made holes to the mould to allow easier clamping of the ribs to the lower and upper blocks. The holes are also a convenient way to carry the mould once the ribs have been glued in place. Last of the ribs to do. Bending the upper ribs seemed to go so fast compared to the rest. I also glued them both to the corner blocks. I first glued one, waited a couple of hours and glued the next, I couldn't wait until the next day. Glueing the ribs to the corner blocks first can be done for the upper bout ribs since the joint doesn't need to be good at the top as the neck mortice is going to be there anyways.

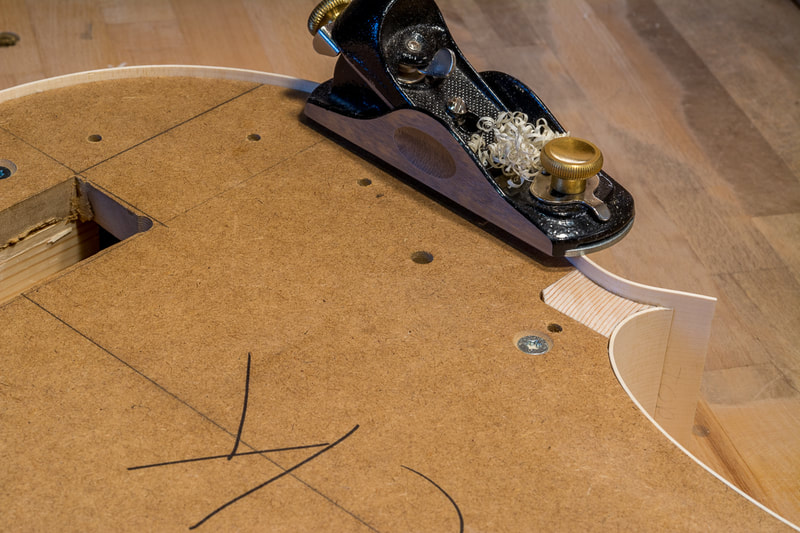

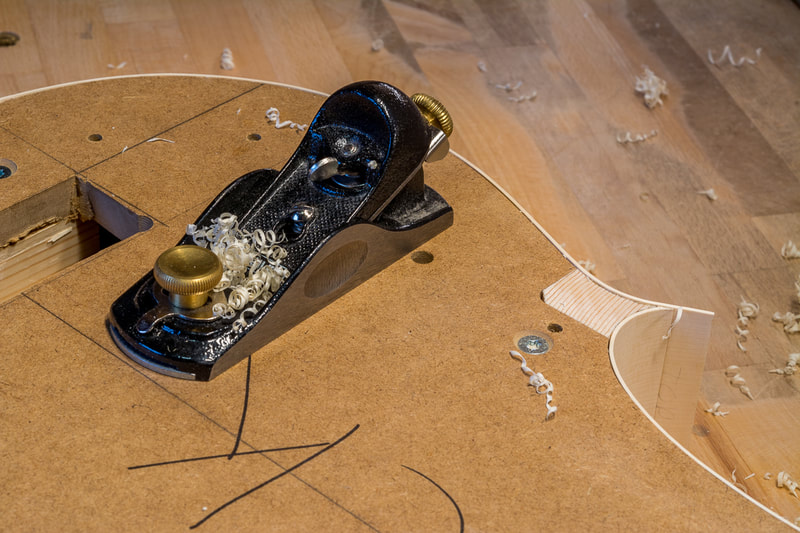

I really enjoy cello making. Today I was thinking about the grain pattern in the upper bouts and how to best make it match the c ribs. Also just handling the wood is so nice. I had planed the ribs nice and smooth and they are silky smooth. Before starting with the upper bout ribs, I trimmed the lower bout ribs so that I don't break them. The height was easy to trim level with the mould with a block plane. It was great to be able trim the ends at the corner blocks properly. I used a fine saw to get close to the line, and then a block plane until I reached the feathered ends of the c ribs. This is something I struggled with last time.

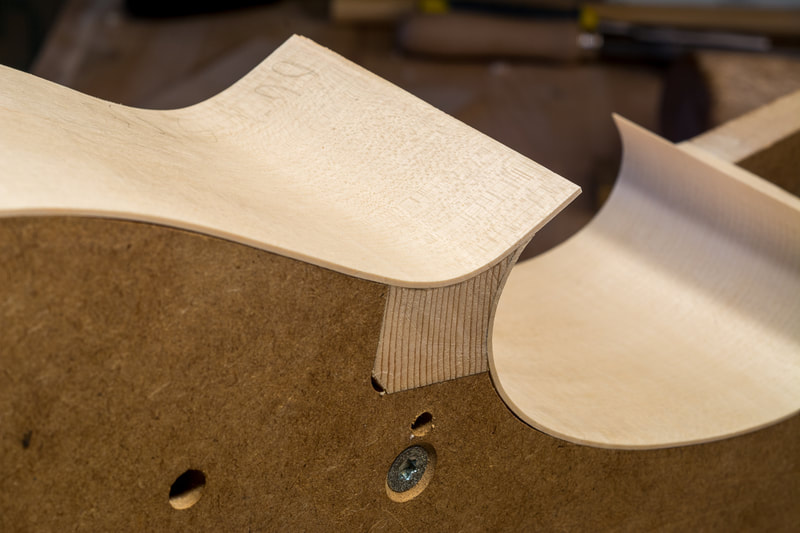

Here's a photo of the joint of the lower bout ribs. It's a tight joint with a pretty close match with the grain. Can't complain too much. The rib on the right could be a little higher I suppose.

The lower block joint had had time to set over night so I could continue to glue the rib to the first corner block. I wasn't too happy with the clamping system used by Strobel in his plans. It was too fiddly, especially in the c ribs. But they are great for ensuring that the lower (and upper) bout ribs closely follow the mould. I used parallel clamps to apply pressure for the actual glue joint to the corner block.

|

AuthorElias keeps growing so a bigger cello will be needed eventually. With the previous cello I had to hurry up a little as Elias needed it already. With this one I want to avoid the pressure. Archives

April 2022

Categories

All

|

RSS Feed

RSS Feed