|

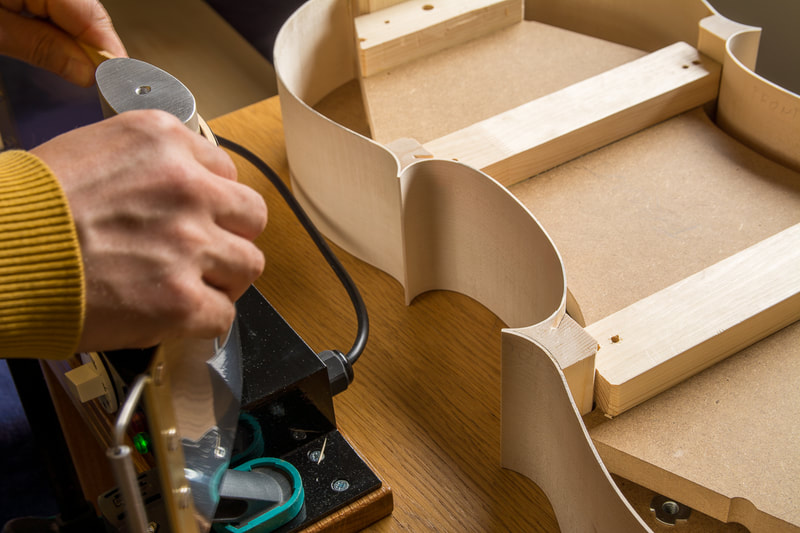

Well, bending the linings is quite tricky. Strobel says they should be bent dry to avoid any warping of the linings later. I found it still almost impossible to bend the linings of the c bouts dry. In the end I did you use water to help the process. I added a wet cloth between the bending iron and the lining. The generated steam makes it possible to bend the linings. The linings for the upper and lower bouts should be easier.

0 Comments

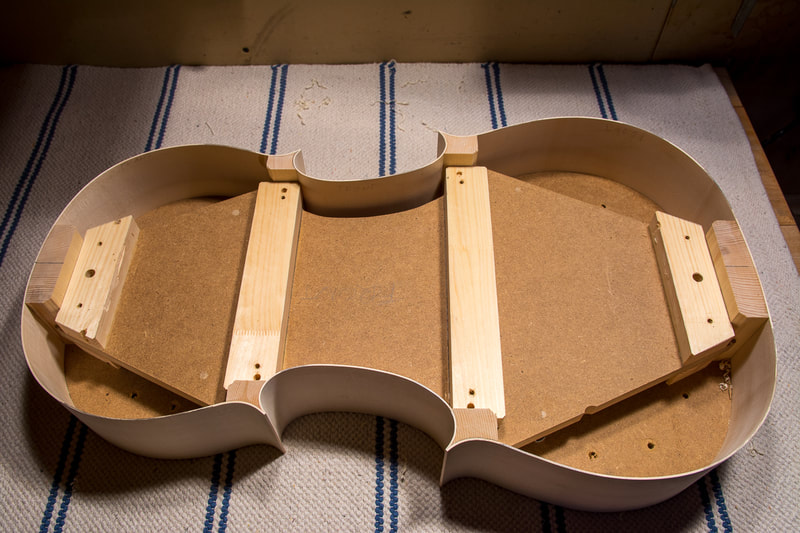

Linings are strips of wood glued to the top and bottom of the sides to add rigidity to the sides, and maybe more importantly, to add glue are when the front and the back are glued to the sides. The linings are typically morticed to the corner blocks. With the last cello I had a lot of trouble with the linings. They kept breaking. This time I bought wood actually meant for the linings. I hope things will go smoother this time. Anyways, I started the work by cutting the mortices into the corner blocks for one of the c bout linings. The practice here also differs. Some cut a rectangular mortice, Strobel saws them at 45° and so will I. Seems easier than trying to chisel them out fully.

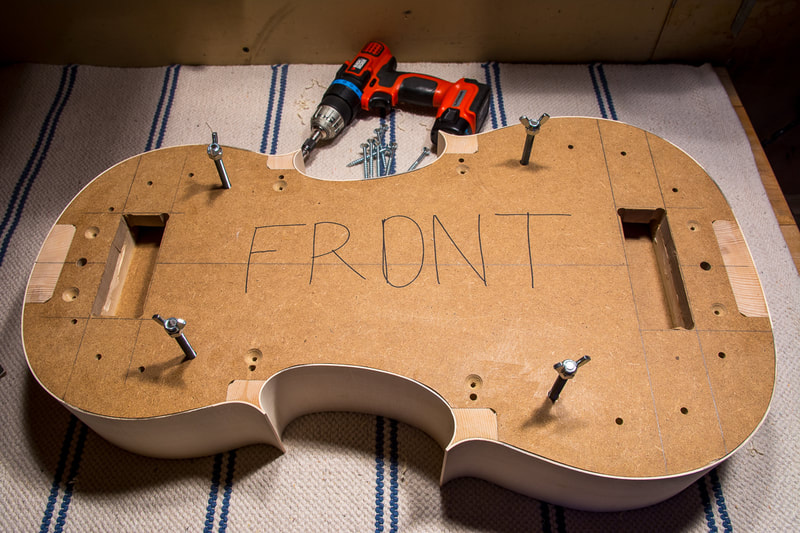

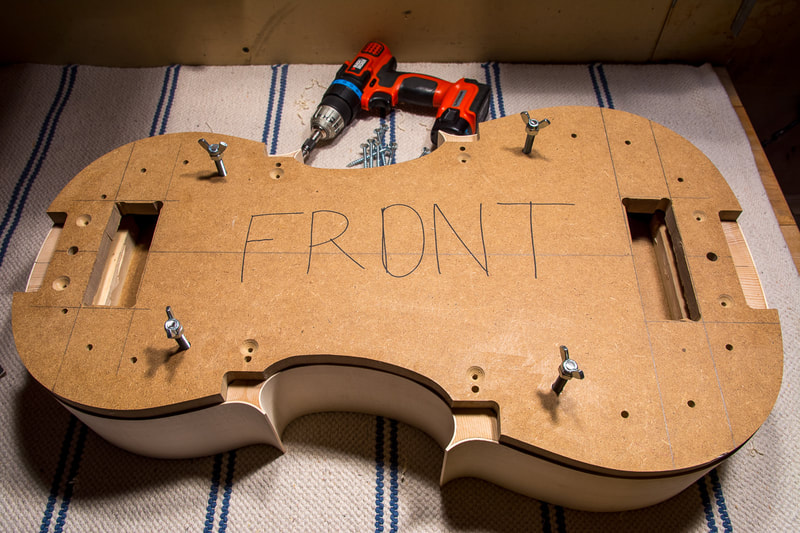

Here are some links to other resources: Youtube: Lucas Fabro MAKING A CELLO | Preparing and gluing the Lining guitars.davidalabaster.com/cello-week-3-the-ribs/ osnesviolins.com/5.Bending%20the%20ribs.htm The mould has almost served its purpose. Time to remove the top of the mould so that I can install the linings. Both sides of the mould have T-nuts on the underside so that the mould can be lifted using some bolts. I also had managed not to glue the plate to the sides so this was very easy. Before I removed the top of the mould I used a pencil to mark where there was a bit of a gap between the sides and the mould so that I can ry to correct that with the linings.

|

AuthorElias keeps growing so a bigger cello will be needed eventually. With the previous cello I had to hurry up a little as Elias needed it already. With this one I want to avoid the pressure. Archives

April 2022

Categories

All

|

RSS Feed

RSS Feed