|

The tabletop with the cross pieces are more or less finished now. I started with the legs today. I rough milled all the lumber for the legs. I knew I didn't have time to all the joinery so I didn't mill the lumber to the final dimensions as it will probably live a little during the week. Instead, I started to look at the joint in more detail. In the mock up I divided the width in three equal parts. It didn't look great to me so I think I will divide it so that the middle part is wider than the sides. This is not quite there yet. I also checked which way the joint looks better. I think the right image here is the way to go. For the proper joint I will make the central part still a little wider though.

0 Comments

Good progress on the tapered sliding dovetails for attaching the legs. Last time I had already created the tails on the cross pieces, this time I routed out the slot on the tabletop. Some fine tuning is still needed and the cross pieces obviously need to be cut to length. Next time I can then already start with the legs if all goes well.

Another great day in the workshop. I sanded the tabletop down to thickness. And started on the joinery. For some reason I only took photos of the underside which has some knots. The foot in second photo is the mock up from pine and both the final one. I just wanted to get an idea of the scale and thicknesses of the various parts. The photo was taken before the final thickness was reached. I think I will make the feet a little wider and the tabletop is already a little thinner. The grain of the elm looks great!

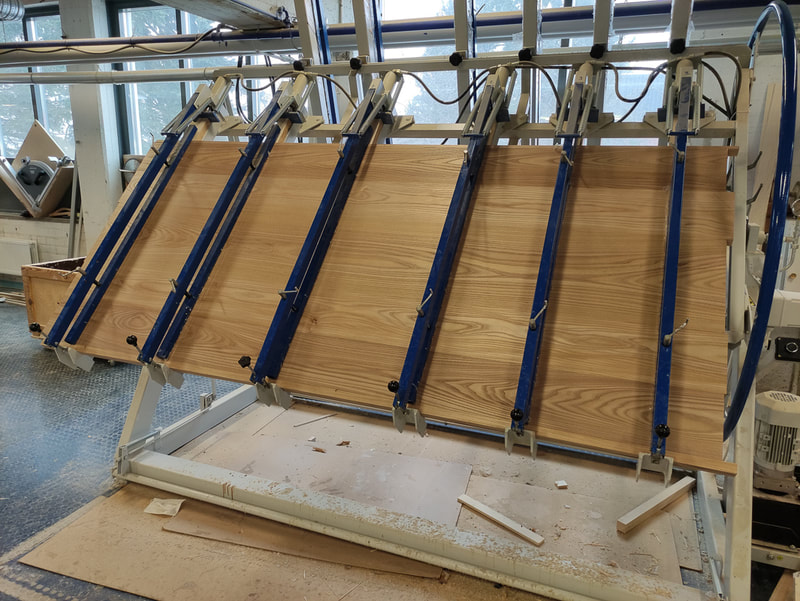

The photos from today look a lot like from last time. The difference is that this time the boards are actually glued together and the tabletop is now in one piece! The glue up went smoothly thanks to the large press which ensures that the boards stay put and good pressure is applied evenly.

Other than glueing up the tabletop I also started working on the dovetails for the two pieces of wood that go across the tabletop below it. They are used both to keep the tabletop straight and to attach the legs to the tabletop. I forgot to take photos of those so I have nothing to show. Next time I will make the matching grooves on the tabletop. Last time I had rough milled the lumber. The boards hadn't warped or anything so this time I went down to almost the final thickness. I left them a little thick so that I can still flatten the table top once I've glued it up. I also got the boards to their final widths, except the two outer boards which I left a little wide for now. I didn't glue up the boards yet but I did a dry run and they all fit nicely together so eh glue up should go smoothly the next time.

I couldn't quite decide the order of the boards. Or in fact, I think I got the order sorter but I can't quite decide which way the the top board on the last two figures should go. I maybe like the last one better. I did some rough milling of the tabletop lumber today. The tabletop should be 100 cm wide. I can make that from 5 boards. I have a nice broad one for the middle and then two more on either side of it. This was just rough milling to get the boards flat. I will not let them rest for a while as they might still live now that I have milled them. I will do the final milling next time.

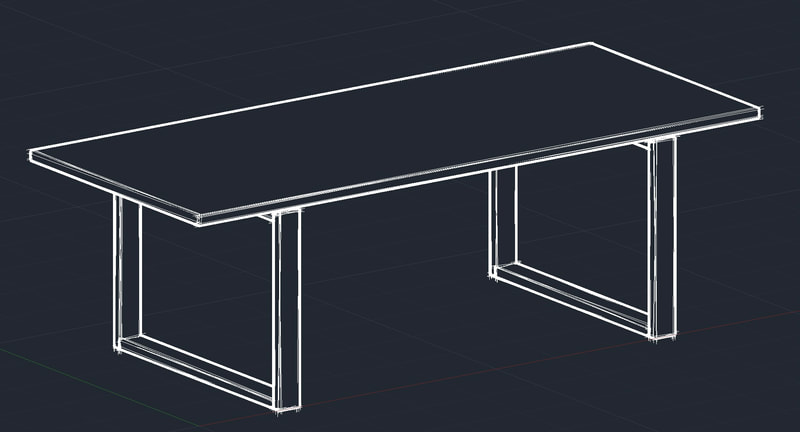

I also sorted out the attachment of the legs to the tabletop. I will use a tapered dovetail to attach a cross beam to the table top and then attach the legs to the cross beam with some reinforcements. The problem here is that the wood in the table lives very differently along and across the grain. The dovetail joint will allow the legs and the tabletop to move independently as the humidity changes over the year. I started working on the next big piece today. It is a dining table for a colleague. She gave me a drawing to show what she had a mind. After thinking about the species of wood for a while we decided to make it also from elm like to desk for my daughter. I had given her a piece of the elm I had used to build the desk and she liked it. Today I started with a mock up of one end of the table, including the legs, or leg. This will help us to check that the dimensions are harmonious and I can figure out how to do the joinery. The tabletop here is thicker than specified. I wanted to see how a thicker tabletop would look like and I can always make it thinner later. I am really excited about this project!

I started studying carpentry last autumn in Keuda, a vocational school in my neighbourhood. Although I've done a lot I want to get some formal qualifications. Studying in Keuda also gives me access to the space and machines to do bigger pieces which I would not be able to do in my tiny workshop at home.

I just finished my first bigger piece. It is a desk for my daughter. She said she would like to have a desk and gave me the dimensions. We then together thought what kind of a desk would be nice for her. This is what we came up with. It is made out of American elm. I haven't worked with elm before so that was nice. I was at first concerned that the figure would be too strong, but I am now really happy with how it all worked out and love the bold grain. I have always been making things I need, and have wanted to learn the skills required to get the job done. My greatest passion is however woodworking. I like how wood feels and smells. And when making with wood I find that the wood guides the maker to reveal the hidden in the piece of wood. I found clay for example very difficult to work with. The constraints set by clay on the craftsman are very different.

Over the years I have made my own clothes, done some metal work, I've made a few things with fiber glass / carbon fiber and epoxy. Mostly to make something and need but also to satisfy my curiosity to know how things work. Below are some pictures of things I've made. A tea pot with cups, a small vase, a canoe and a snow lantern. In this workshop blog my intention is to document some of the stuff I do. I will probably mostly concentrate on woodworking. I want to get more serious about it, hopefully make things not just for myself and those closest to me but to a wider audience. |

AuthorI have always been making things I need, and have wanted to learn the skills required to get the job done. My greatest passion is however woodworking. Archives

May 2022

Categories |

RSS Feed

RSS Feed