|

I cut the bottom supports of the table to length and covered the ends with plugs made from the same pieces of wood. The supports don't go continuously through the while width of the table to allow the wood to contract and expand with the seasonal variations in humidity. I also attached the legs to the supports and cut the table to width. The cutting of the table to width was rather nerve-racking but it went pretty well in the end, only minor burns on the wood which I could remove with a plane. I still need to fit and fix the smaller cross supports before I can apply the finish. So a little way to go still but not all that much.

0 Comments

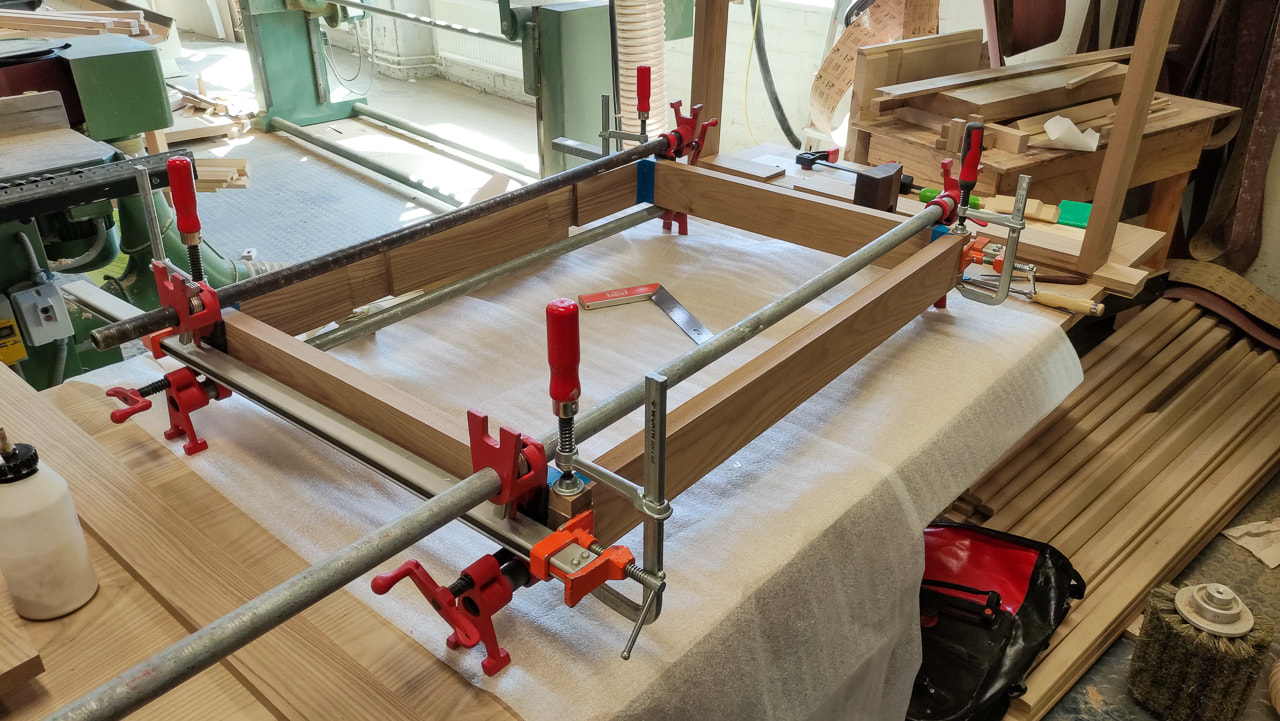

I managed to fit all the pieces together and glue the legs together. Everything went really well without any issues. I used a chisel and a router plane to fit the finger joints. I haven't used a router plane a lot but it suited the job perfectly. It was really easy to thin shavings from the tenon to get a perfect fit. There will probably be no more gluing, all the remaining pieces will be screwed together.

I had a great day today! I milled all the remaining pieces to final dimensions. And also managed to do all the joinery at least roughly. For the joinery I need to still fit but the bulk of the work is done. I forgot to cut the cross pieces to length so that also still needs to be done. If all goes well, next time I might be able to turn the table on its legs.

The tabletop with the cross pieces are more or less finished now. I started with the legs today. I rough milled all the lumber for the legs. I knew I didn't have time to all the joinery so I didn't mill the lumber to the final dimensions as it will probably live a little during the week. Instead, I started to look at the joint in more detail. In the mock up I divided the width in three equal parts. It didn't look great to me so I think I will divide it so that the middle part is wider than the sides. This is not quite there yet. I also checked which way the joint looks better. I think the right image here is the way to go. For the proper joint I will make the central part still a little wider though.

|

AuthorI have always been making things I need, and have wanted to learn the skills required to get the job done. My greatest passion is however woodworking. Archives

May 2022

Categories |

RSS Feed

RSS Feed