|

I got the last delivery I have been expecting today. It contained some washers and a nut for the engine and some parts for the carburetor. I tightened and secured a couple of nuts and also cleaned and changes the gaskets on the carburetor. The engine is pretty much ready to go on the frame again.

0 Comments

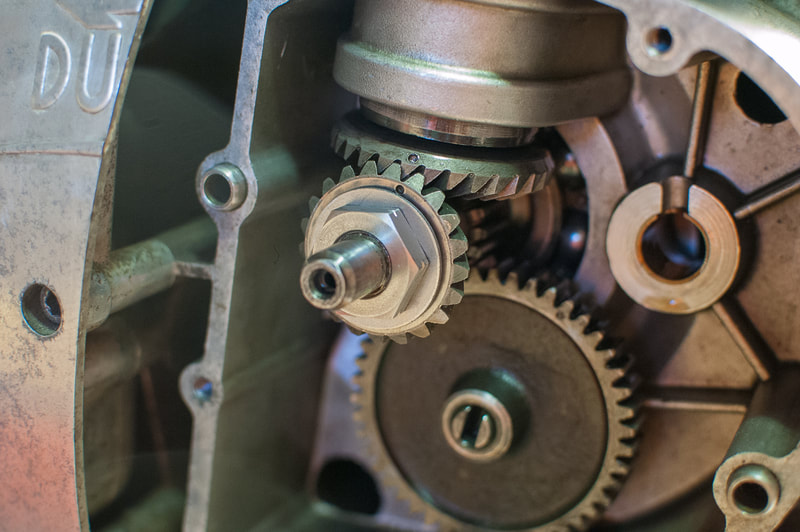

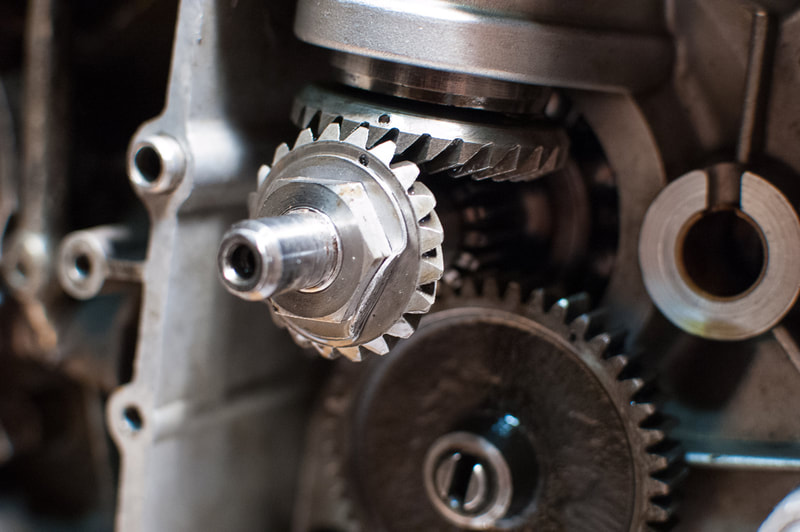

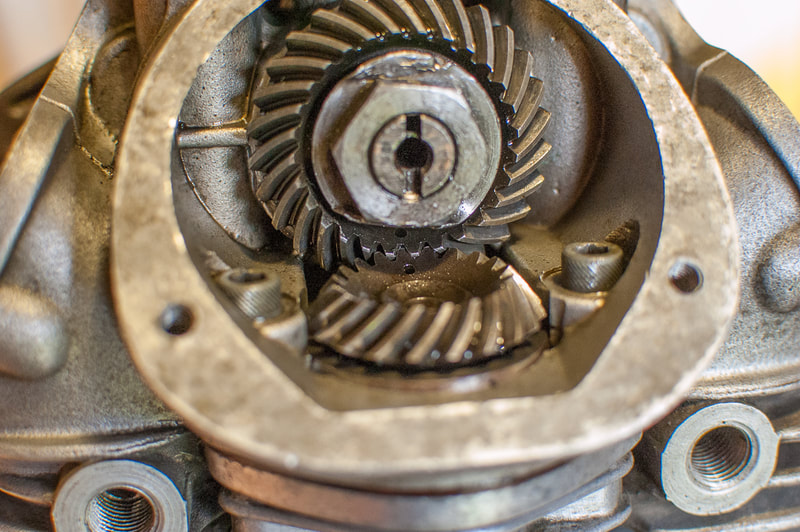

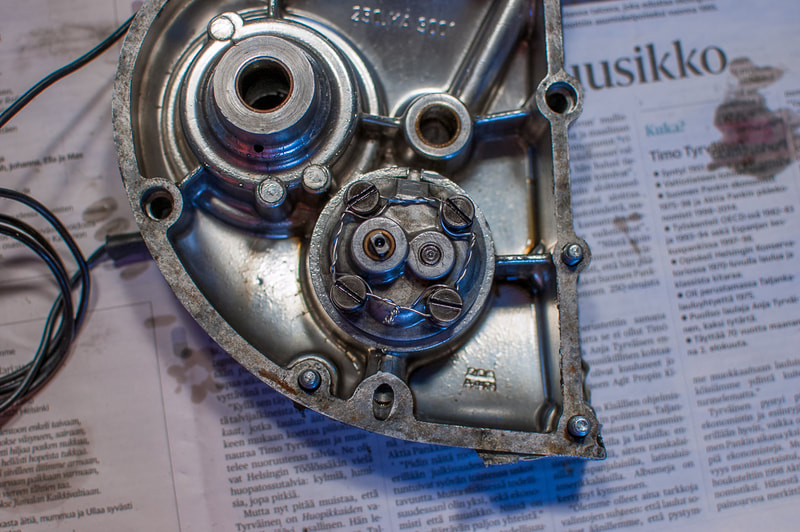

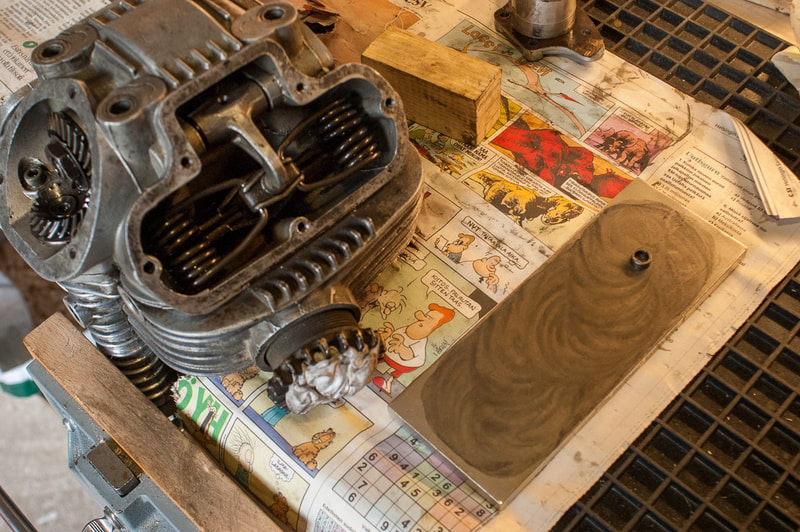

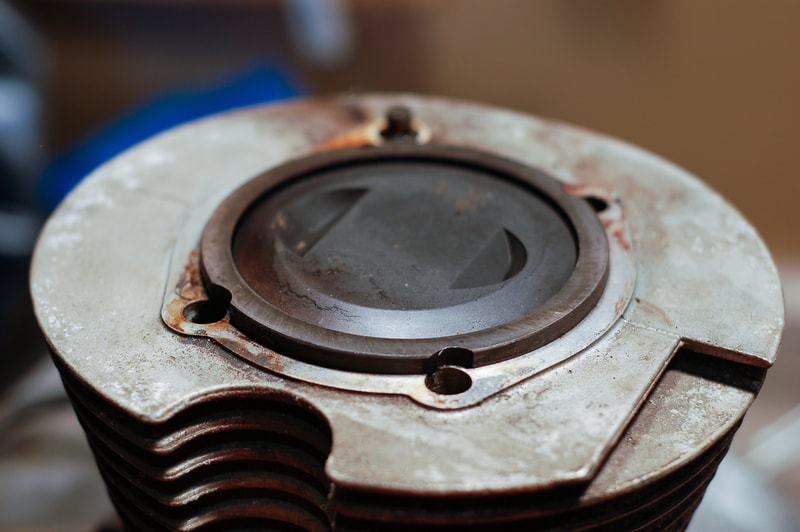

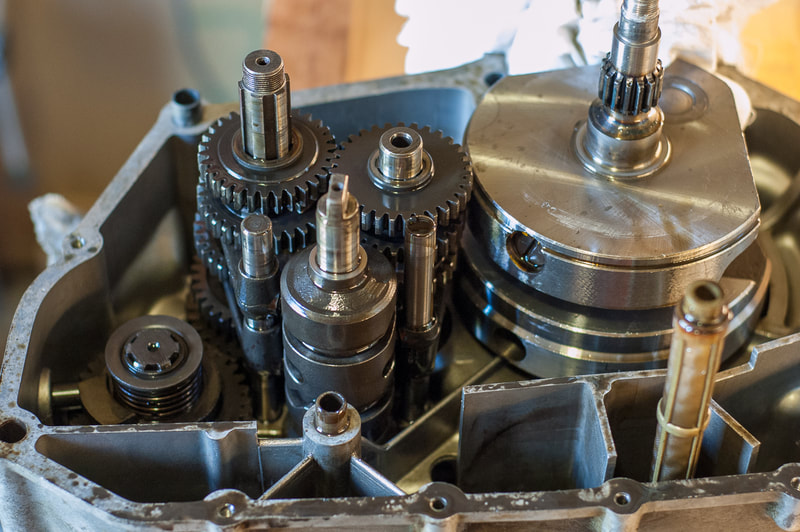

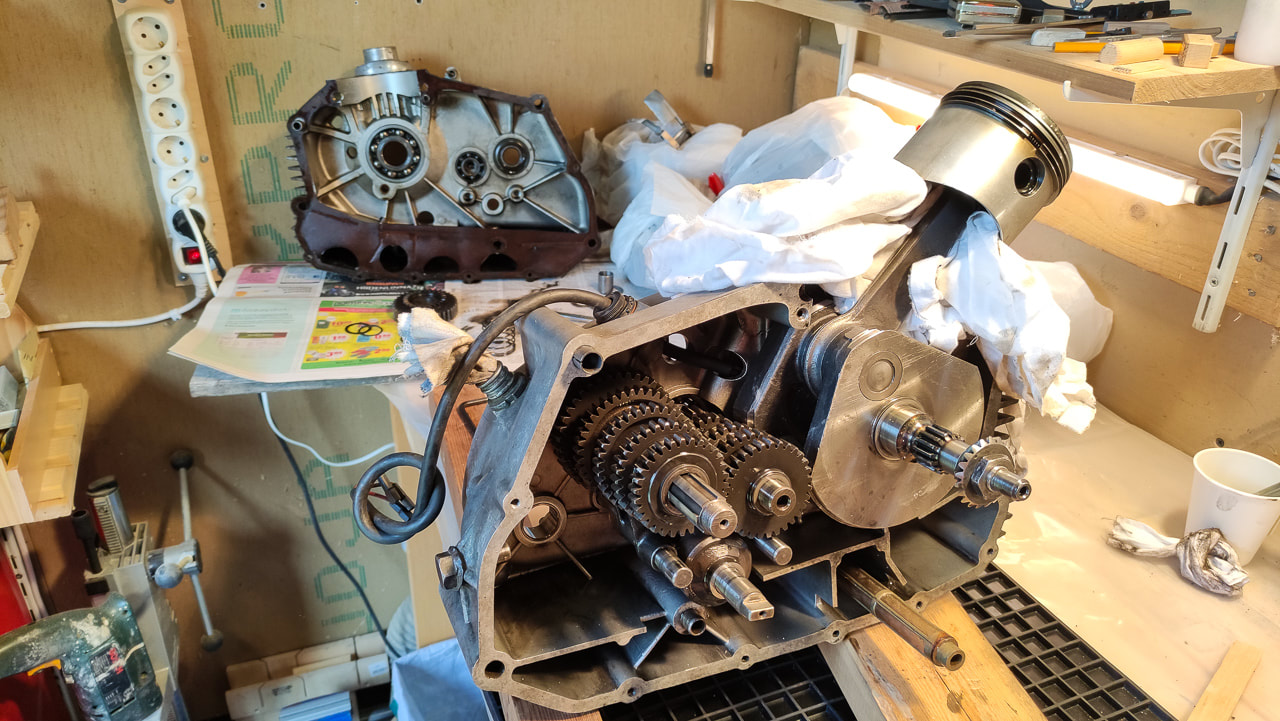

The engine is starting to look like an engine again. Today I put the cylinder and cylinder head back on their places again. I renewed all the gaskets on the way. At this stage it is important to align all the gears connecting the valves to the ignition to ensure correct timing of the ignition. The last gear which controls the ignition has a dot and a line. The line is for this 450 cc model, the dot is for all other models I believe.

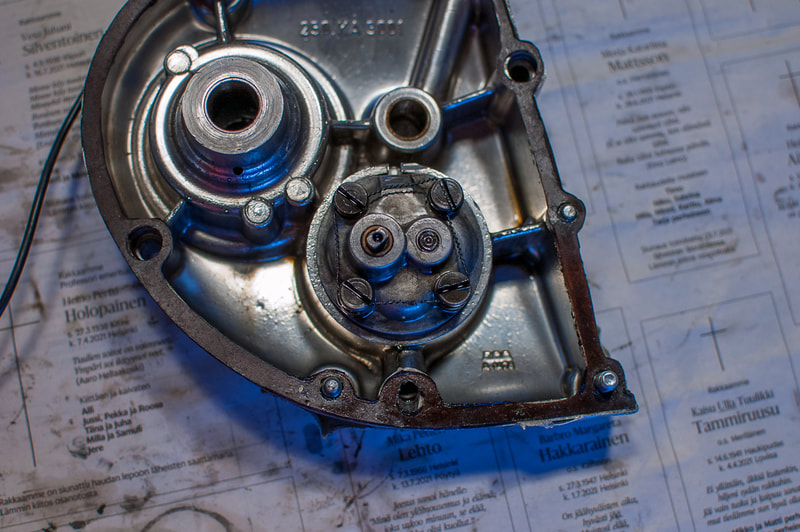

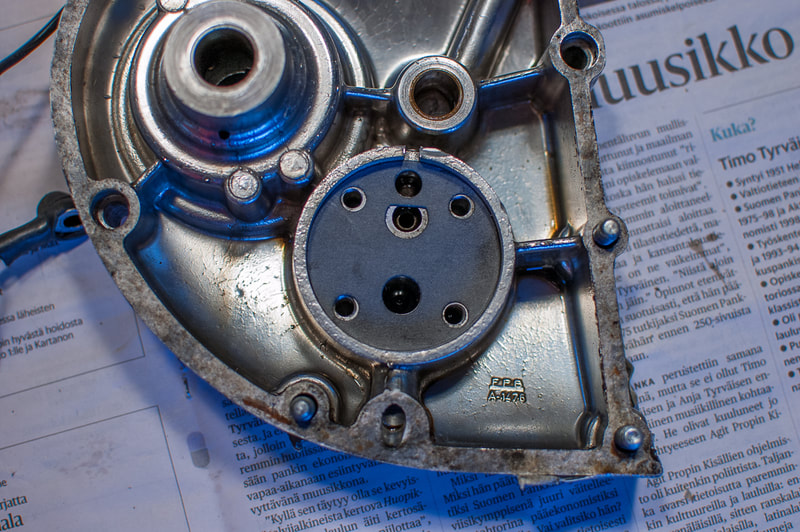

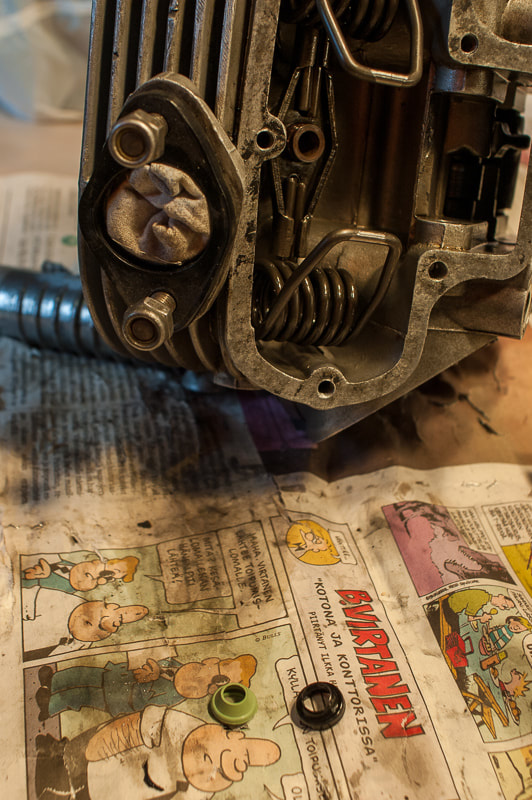

I bought some more washers etc. which should arrive tomorrow. Once they come I can tighten all the remaining nuts, renew the final gaskets and close the engine for now. I am not quite ready to start the engine though. The battery I bought has not yet arrived. I changed the oil pump gasket today. The screws are secured by a locking wire which scared me at first but I thought that since I have a new gasket I should change it. The pump seemed in good condition so I only changed the gasket. I didn't measure any tolerances etc. but I hope the visual inspection is enough.

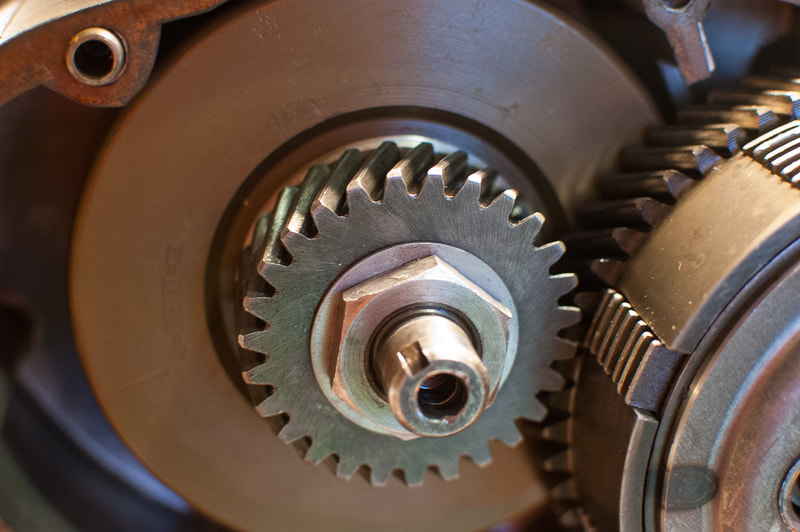

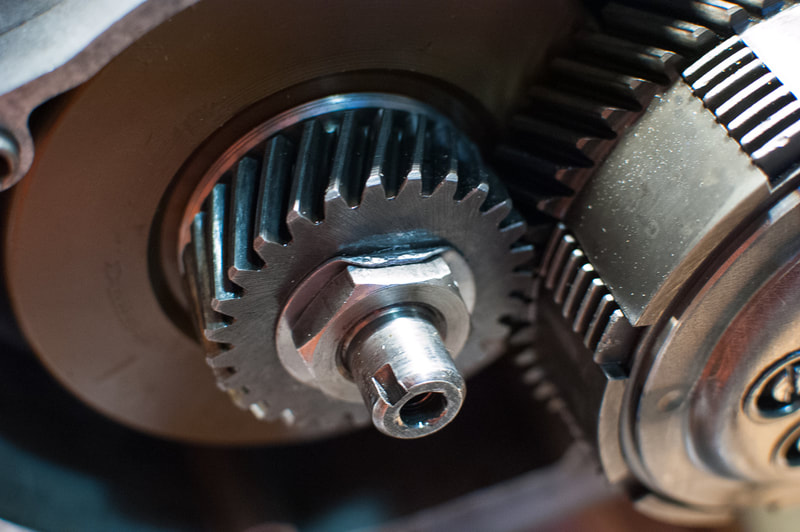

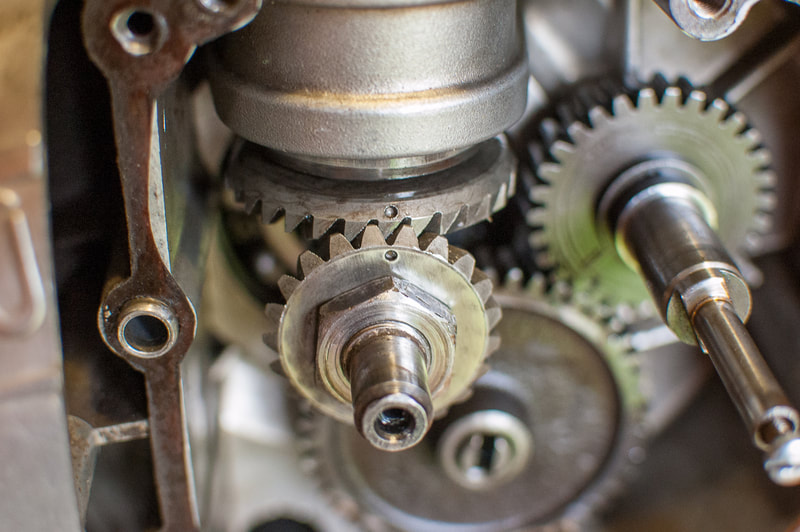

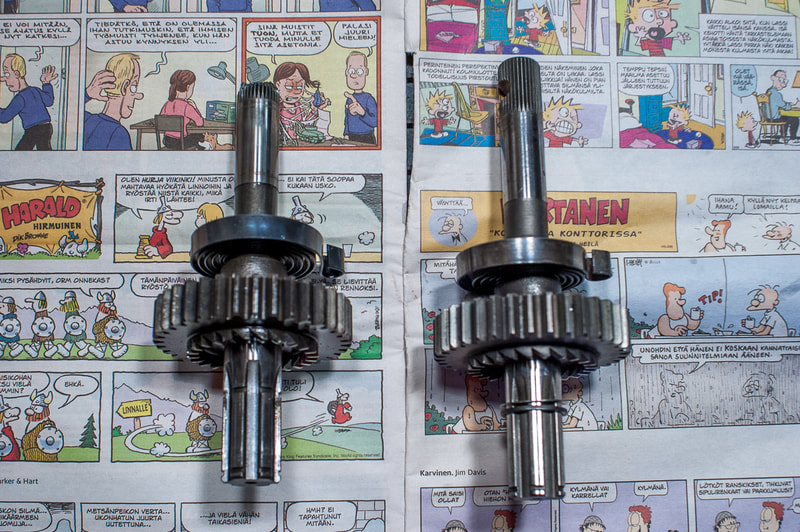

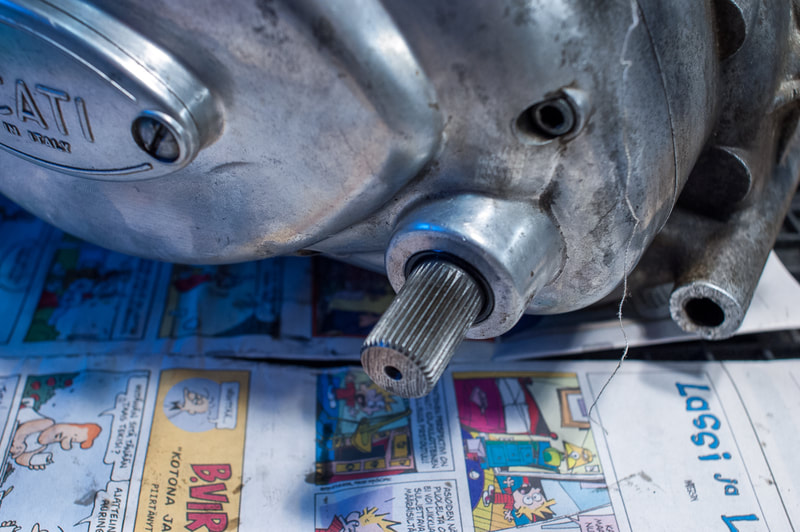

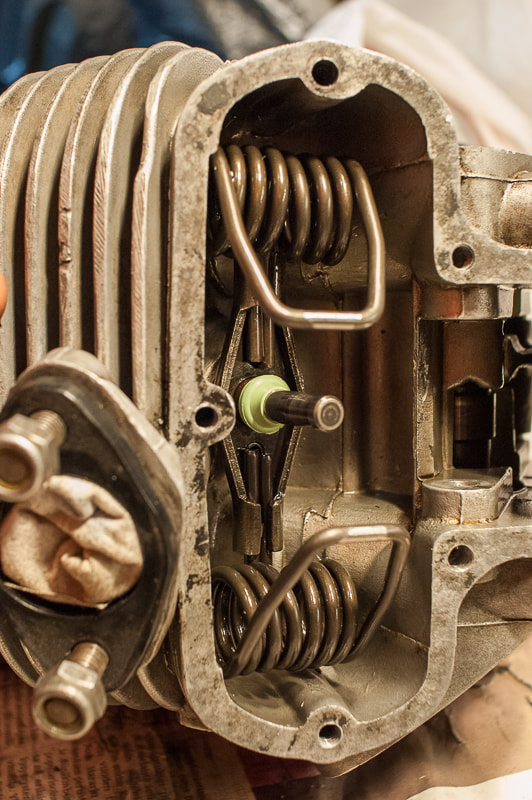

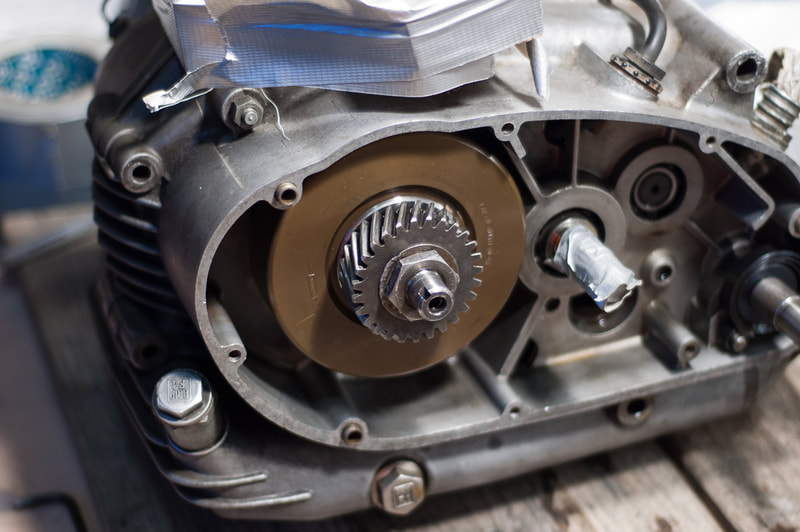

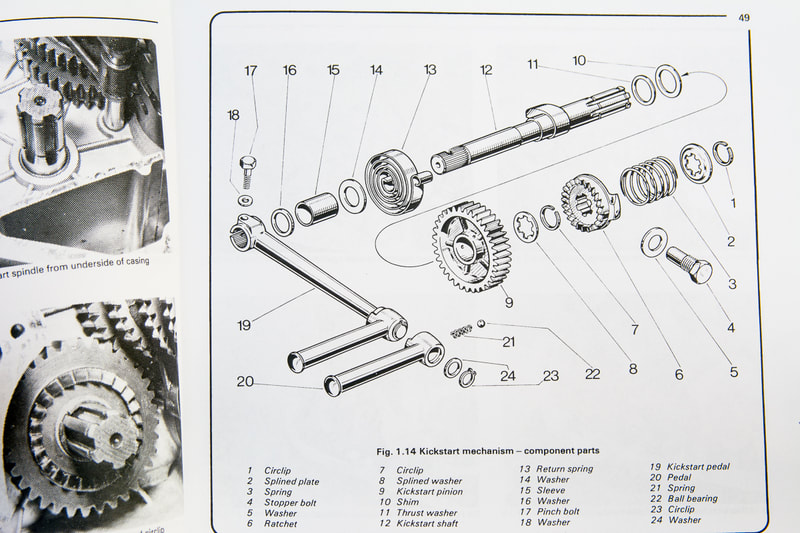

The long awaited part arrived today! It is used but in good shape. It came with the gear and spring. The spring on mine seems to be in better shape so I took the spring from the old one but used the gear from the new part.

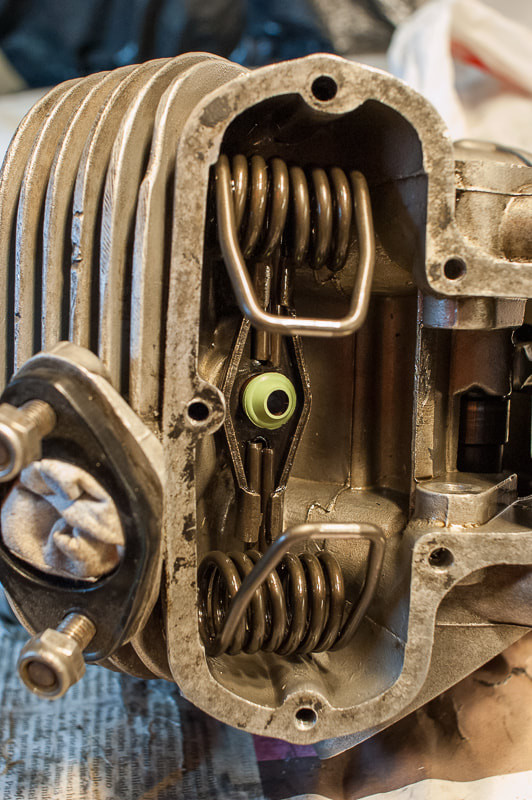

I can almost put the engine together again. I am still missing third order for some small parts like nuts and washers and a few bits (seals etc.) for the carburetor. I checked and adjusted the valves today. I have two different sources for the valve clearances. One says 0.05 - 0.10 mm for both valves, the other 0.08 mm for inlet and 0.13 mm for the outlet. I followed now the looser ones as I have understood that having the clearances too small is worse and too large. Both valves were a little too tight so I used my diamond bench stone I use to sharpen my tools to get a bit off the shims. I also changed the valve seals. They were included in the set of o-rings and other seals I got with my order yesterday. The old ones were hard and very brittle. I first thought they are metal or something but they broke easily. Definitely the time to change the seals.

The package contained lots of seals and I don't quite know where they all belong. Need to figure that one out. One is for the ignition cover, and the one I really wanted is for the camshaft tube flange. Anyways, good that I bought the whole set. I wouldn't have thought about the valve seals otherwise. I have been doing quite a a lot recently although I haven't really kept up with these blog posts or even photos. I soldered the fuel tank. I might still line the tank with something like Por 15 or similar to prevent it from rusting and helping to fix the leak. I've also done a lot of cleaning of various parts. Yesterday I took the valves out and cleaned and lapped them. Next up is to tune the valve clearances. Both of the valves have too small clearances which I should be able to fix by just carefully sanding a little of the shims with fine sand paper.

The fuel tank has two fuel taps, one on either side. Unfortunately there are leaks around both of them. Last time I tried to just fill them with some epoxy putty. Unfortunately that didn't work. Now that I am waiting for the spare part for the engine I am trying to fix the leaks for good. I first cleaned up the putty. In the photo below you can just about see the hair crack. I will solder the cracks and hope that works. I will not paint the tank before I have used the bike again for a while to ensure the fix really works.

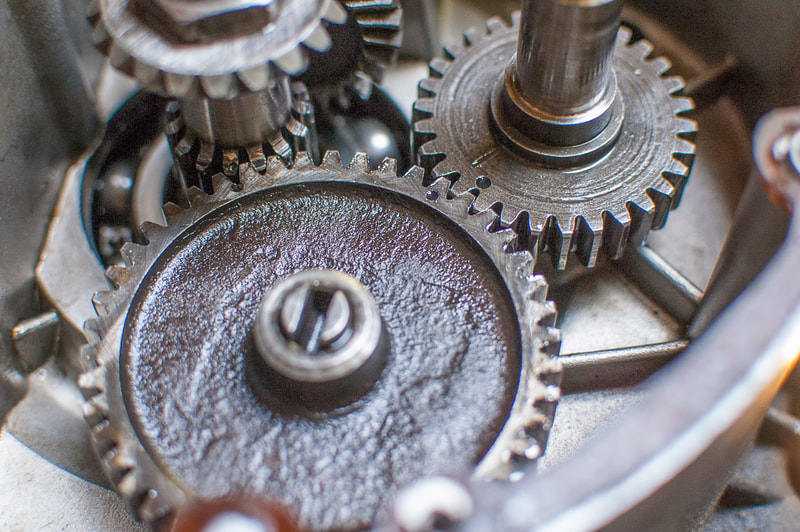

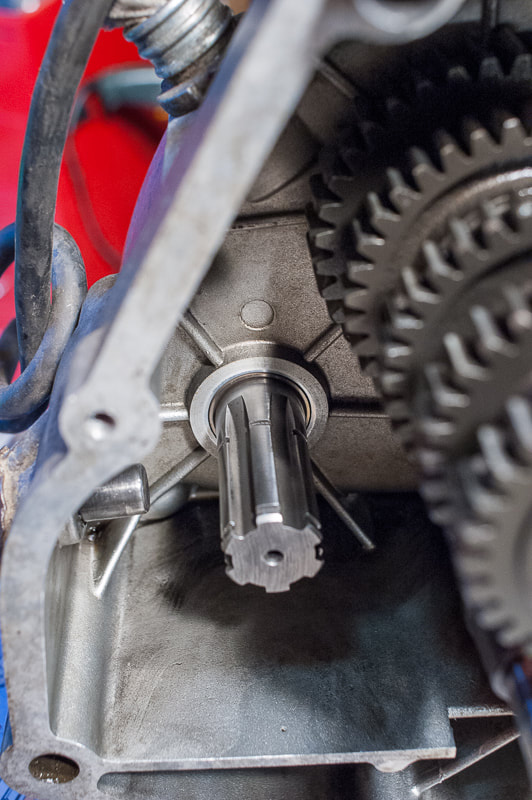

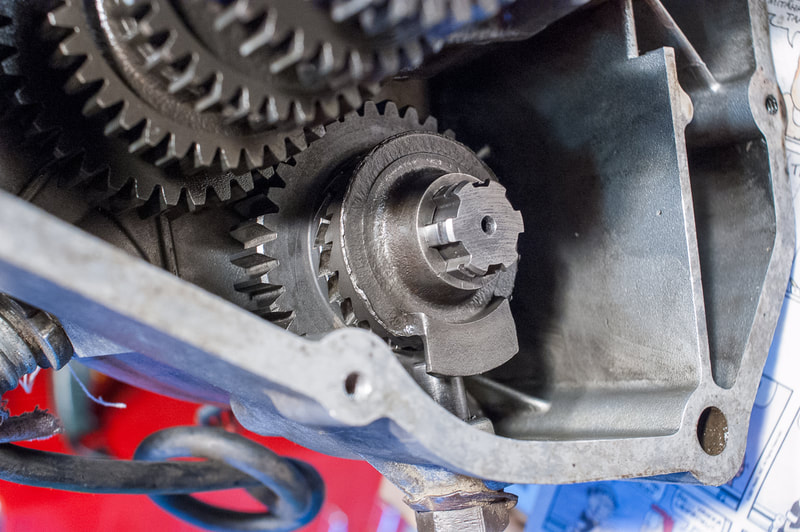

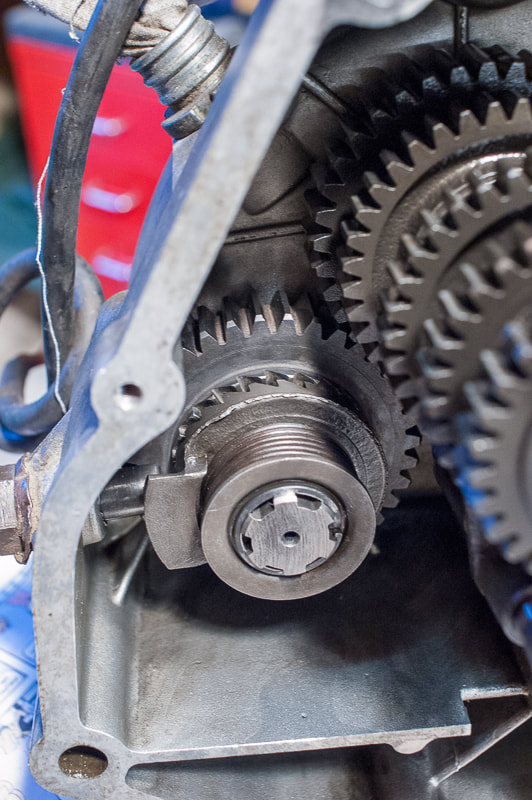

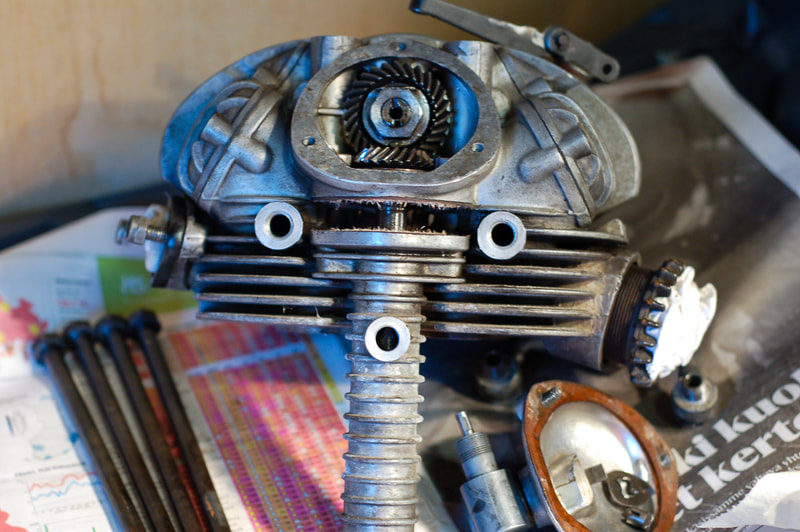

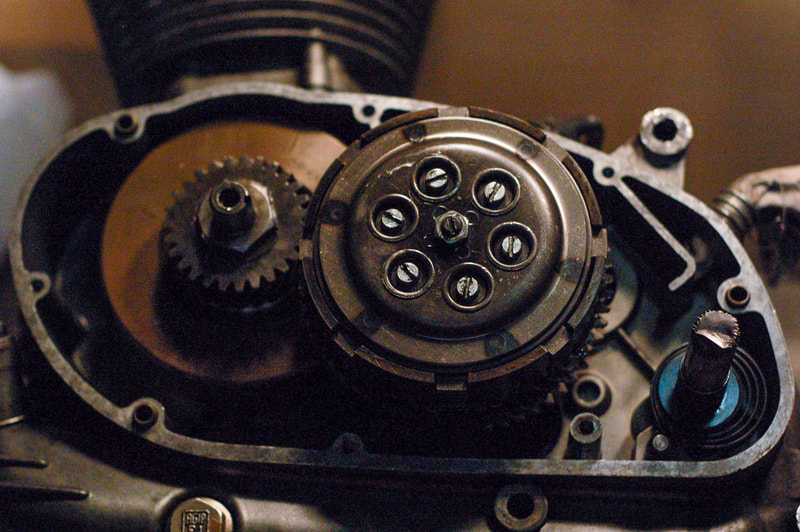

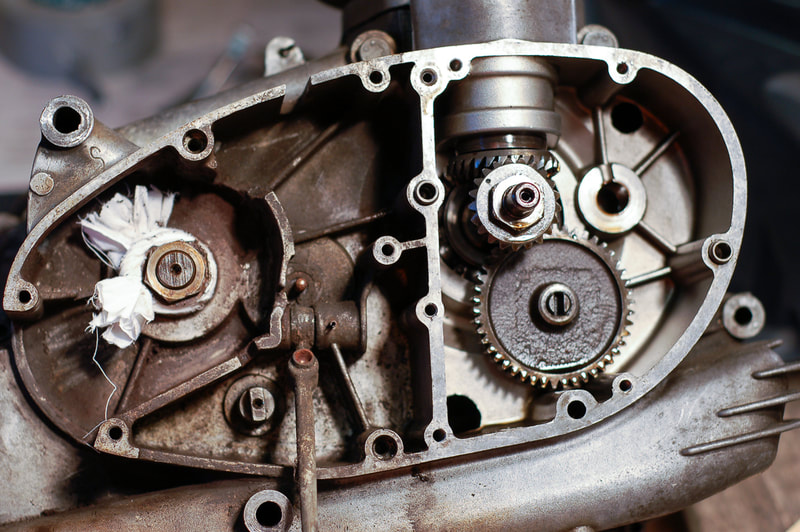

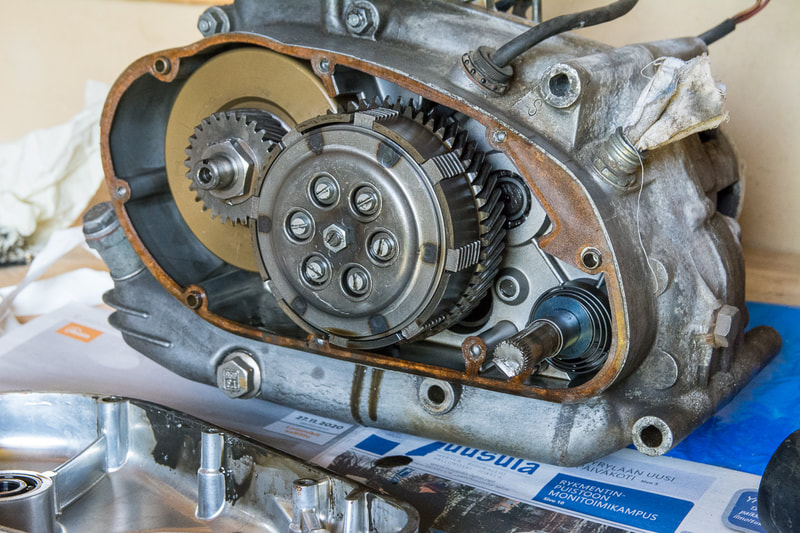

Time to get the part out so that I can order a new one. In order to get the part out, I need to separate the engine body halves. The disassembly starts with the remove of the cylinder head. That is pretty straight forward. After the cylinder head is away, the manual instructs to disassemble the left side first followed by the right side. Once some nuts and gears are removed from the right side, the two halves just come off after the bolts keeping the sides together have been removed. The kickstart shaft comes out very nicely after that.

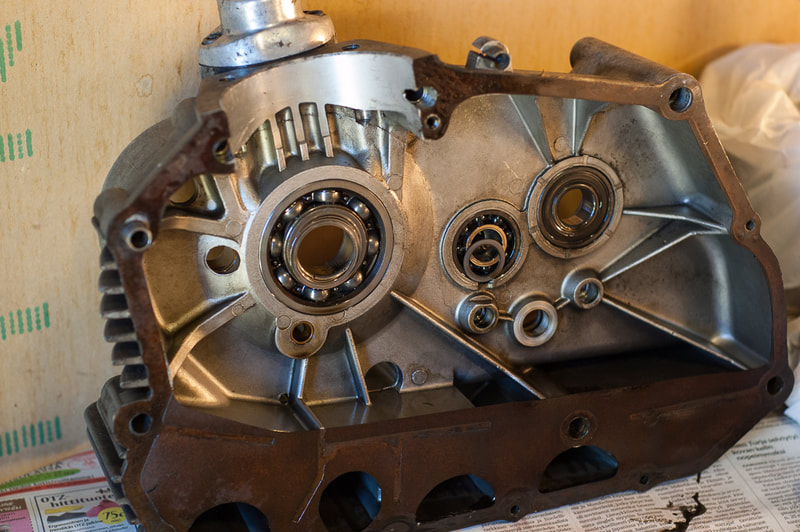

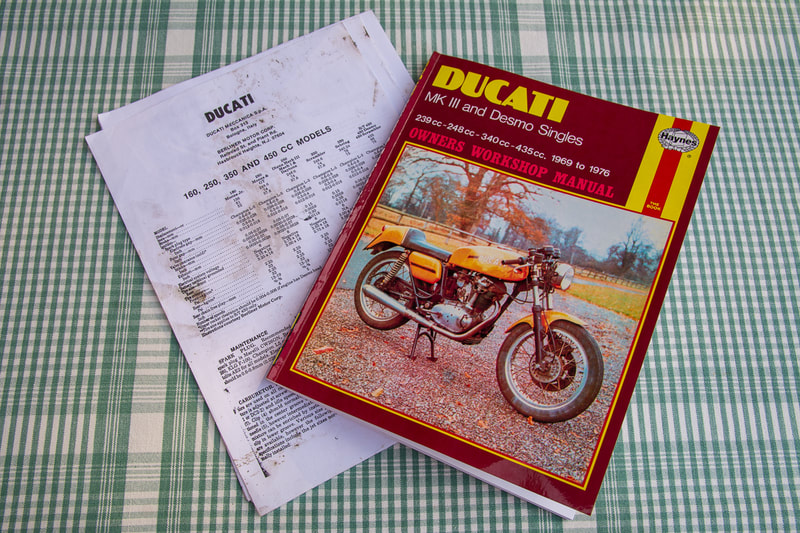

Now that the part is out I can order the replacement part. There are several places to find spare parts. Ebay obviously, where I actually found a part that looked to be in good shape with a good price. So that should be arriving in August. I also found two sites which look really good. Now that the engine is open I will have a good look at the parts and order other bits I might want to replace. Gaskets for sure. The sites I found best are www.ducativintagestore.com and www.ducaticlassics.com. I packed all the separate units making up the engine into to plastic bags. That way everything stays clean and I don't have to reassemble the engine but I can still easily put the engine into storage somewhere and free the workshop for other stuff until the spare part comes. I have some printouts and a book on the old Ducatis. I couldn't quite figure out from the figures how the kickstarter shaft is located so I decided to open the one side quickly and check how much of the engine I need to disassemble. Looks like I need to take the whole thing apart. I haven't worked a lot with engines. In fact I have only taken this one to pieces before. But I do remember always wondering how clean they are from the inside. And it should stay that way. Before I open the engine further I need to clean up the engine from the outside properly. I really should have done that before opening it this far...

Quite frustrating that I need to take the whole thing apart. That's what I feared. I don't really have space for everything in my small workshop. Especially if I want to continue building Cello #2 at the same time. |

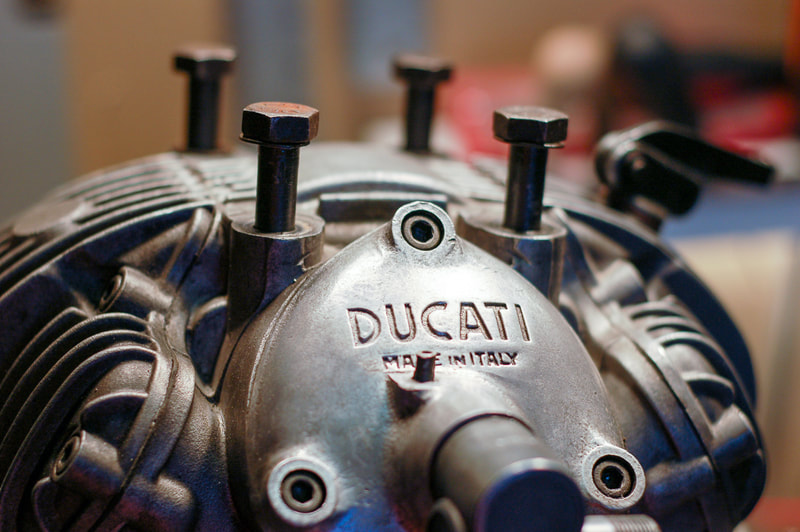

Ducati 450 Mark 3Fixing an old Ducati motorbike from 1971. ArchivesCategories |

RSS Feed

RSS Feed